Hello everyone! Today I am happy to introduce you to an important component that plays a key role in fiber optic networks – the fiber splice case. As the core equipment for protecting and managing optical fiber fusion splicing connection points, optical fiber splice boxes play an indispensable role in ensuring the reliability and stability of optical fiber transmission. In this article, I will give you a detailed analysis of the basic concepts, typical structural characteristics, and wide application of fiber optic splice boxes in various types of fiber optic networks. I believe this will help you better understand and utilize this important product.

Basic overview of fiber optic splice boxes

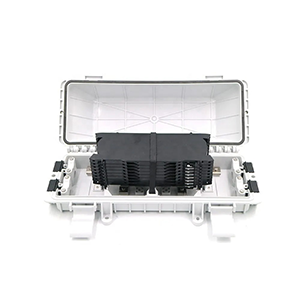

An optical fiber splice box is a device used to manage, connect and protect optical fiber connections. It usually consists of a rugged housing, fiber optic fixtures, and a sealing system. Its main function is to provide a safe environment to connect fiber optic connectors together and protect these connectors from physical damage, dust and moisture, etc. from the external environment.

Definition and function of optical fiber splice box

- The optical fiber splice box is a special optical fiber connection device, mainly used to fix and protect the splice points of optical fibers.

- It provides an enclosed, protected space for installing and fixing fiber optic connectors connected by fusion or mechanical means.

- The optical fiber splice box can effectively prevent the splice point from being damaged by the external environment and ensure the reliability and stability of the optical fiber connection.

The key position of optical fiber splicing box in optical fiber fusion splicing

- Fiber fusion splicing is one of the main methods of optical fiber connection, which requires two optical fibers to be accurately aligned and fused together.

- The optical fiber splicing box provides a safe and stable installation environment for the splicing point, ensuring the quality of splicing and avoiding fiber breakage or damage caused by external factors.

- It also provides proper protection and support for fiber optic connections, reducing bending stress and extending fiber life.

- Therefore, the optical fiber splicing box plays a vital role in the optical fiber fusion connection link.

The importance of fiber optic splice boxes in protecting fiber optic connection points

- The optical fiber connection point is the most fragile part of the optical fiber network and is easily damaged by external environmental factors.

- The optical fiber splice box adopts a sealed design, which can effectively block dust, water vapor, corrosive gases and other external factors from damaging the optical fiber.

- At the same time, the splice box also provides mechanical protection to prevent the splice point from being damaged by external forces such as squeezing and pulling.

- Through these protection measures, the optical fiber splice box greatly improves the damage resistance and reliability of the optical fiber connection point.

In general, fiber optic splice boxes are an indispensable and important component in fiber optic networks. It plays a vital role in fiber fusion splicing and protection of fiber splicing points, ensuring the stable and reliable operation of the entire fiber link. Therefore, the selection and installation of fiber optic splice boxes are crucial to the construction of fiber optic networks.

Introduction to the structure and characteristics of optical fiber splice boxes

The optical fiber splice box has good protection performance, flexibility, easy installation and maintenance, and efficient connection characteristics. It is one of the indispensable and important components in the optical fiber network. Below, I will introduce to you its components and related Features.

Shell

- The casing is usually made of metal, such as aluminum alloy or stainless steel, which has excellent mechanical strength and corrosion resistance.

- The shell design is compact and sturdy, and can effectively resist external mechanical forces such as impact and extrusion.

- The surface of the shell is epoxy powder sprayed or anodized to improve the protection level and aesthetics.

- The casing is equipped with a well-sealed cable/fiber inlet and outlet to ensure that the internal space of the splice box is sealed.

Fiber optic fixture

- Fiber optic fixtures are usually made of metal or engineering plastics to ensure long-term reliability.

- The fixing device is equipped with optical fiber brackets, fixing clips, etc., which can adjust the bending radius of the optical fiber and control the bending stress.

- Some high-end splice boxes are also equipped with fine-tuning mechanisms to facilitate precise positioning of optical fiber connectors.

- The fixing device is reasonably designed to ensure that the fiber optic connector is firmly installed and will not be displaced due to external force.

Sealing system

- The sealing system consists of various sealing rings, fillers and other components to ensure the complete sealing of the internal space of the connection box.

- Common sealing materials include rubber, silicone, etc., which can effectively block the intrusion of dust, water vapor, chemicals, etc.

- The sealing system is designed with multi-level sealing in key parts such as wiring ports and cover joints.

- Some splicing boxes for special occasions also use vacuum sealing technology to achieve reliable sealing in vacuum environments.

Other components

- The cable entry bracket is used to fix and smoothly introduce optical cables to alleviate the impact of external forces on optical fibers.

- The management space provides sufficient bending radius and organization area for fiber optic cable entry and exit.

- The monitoring system integrates temperature and humidity sensors, fault detection and other functions to monitor connection quality in real time.

- Some high-end connection boxes also have remote communication interfaces to facilitate status monitoring and fault diagnosis for managers.

The optical fiber splice box provides comprehensive protection and management functions through its structure and features to ensure the stability, reliability and long-term use of the optical fiber connection. Key components such as its sealing system and optical fiber fixtures provide important guarantees for the stable operation of optical fiber connections under various environmental conditions.

Main types of fiber optic splice boxes

Different types of fiber optic splice boxes have different characteristics and applicable scenarios. The appropriate type can be selected according to specific network requirements and installation environment. Fiber optic splice boxes can be divided into the following main types according to their uses and installation environments:

Indoor wall-mounted fiber optic splice box

- This type of connection box is mainly used in indoor computer rooms, data centers and other environments.

- The outer casing is mostly made of metal or engineering plastics, and its appearance is compact and beautiful, making it easy to install on the wall.

- Small size, capacity usually between 4-24 cores, suitable for small LAN or building optical fiber network.

- The sealing performance is relatively weak, mainly protecting against dust and human operations, and is suitable for relatively dry and clean indoor places.

Outdoor buried fiber optic splice box

- This type of junction box is mainly used in outdoor underground pipeline networks or overhead lines.

- The shell is made of waterproof and dustproof metal material, which can withstand harsh outdoor environments.

- Large in size, it can accommodate fiber fusion splicing of more than 48-96 cores, and is suitable for the splicing needs of trunk networks.

- Using multiple sealing designs, it can effectively block moisture, dust, chemical corrosion and other factors.

- Usually equipped with anti-theft locks to improve safety and protection.

Cabinet-mounted fiber optic splice box

- This type of connection box is specially suitable for occasions such as computer rooms and data centers where network equipment is concentrated.

- The shell size is designed to meet the installation requirements of 19-inch standard cabinets and facilitate centralized management.

- Large capacity, can accommodate fiber splicing of more than 96-288 cores, meeting the needs of large-capacity networks.

- There is a complete optical fiber management system inside, including fiber optic brackets, bending radius control, etc.

- Some models also have monitoring and management functions, allowing you to view the connection status remotely.

Branch fiber optic splice box

- This type of splice box is mainly used for branch and aggregation of optical fiber networks to achieve local connection flexibility.

- The shell size is relatively small, the capacity is between 4-12 cores, and it is suitable for splicing branch optical fibers.

- The internal structure is removable, making it easy to add or replace optical fiber connectors on site.

- Commonly used as user branch access points for FTTH and other access networks.

In summary, different types of fiber optic splice boxes differ in size, capacity, applicable scenarios, etc., and they need to be selected based on actual application requirements. The indoor wall-mounted type is suitable for small LANs, the outdoor underground type is more suitable for trunk networks, and the cabinet-mounted type is suitable for large-capacity computer room scenarios. Branch-type connection boxes provide flexible branch connection solutions. Only by selecting the appropriate type of splice box can the safe and reliable operation of the optical fiber link be ensured.

How to install and maintain fiber optic splice boxes

Regular maintenance and inspection can detect and eliminate potential problems in time to ensure the normal operation and signal transmission quality of the fiber optic splice box. The installation and maintenance of the fiber optic splice box includes the following steps and precautions:

Installation of optical fiber splice box

- Select the appropriate type of connection box according to the site environment, such as indoor wall-mounted, outdoor underground, etc.

- Make sure the installation location is convenient for subsequent maintenance and operation, and away from harmful factors such as high temperature, moisture, vibration, etc.

- Read the product manual carefully and follow the steps for correct installation, including fixing the base, introducing optical cables, splicing optical fibers, etc.

- Pay attention to keeping the inside of the connection box clean and dry to avoid dust and water vapor from entering and affecting use.

- For outdoor connection boxes, it is necessary to focus on checking the integrity of sealing rings, waterproof joints and other parts.

- After the installation is completed, it is recommended to conduct a connectivity test to ensure that the quality of the optical fiber connection is up to standard.

Daily maintenance of optical fiber splice boxes

- Regularly inspect the appearance of the splice box and check whether the shell and seals are damaged or aged.

- Clean the inside of the connection box, such as sweeping away dust, wiping the connector end faces, etc., and keeping it clean and dry.

- Check whether the optical fiber fixing device is firm and whether the optical fiber bending radius meets the requirements.

- Check the connection status of each joint and welding point to ensure that there are no looseness, damage or other problems.

- If necessary, optical power meters and other testing equipment can be used to measure the transmission quality of optical fiber links.

- For monitoring connection boxes, regularly check the working status of sensors and communication interfaces.

Common faults and troubleshooting measures

- The optical fiber is broken or the connector is loose: Check whether the fixing device is loosening, re-fix or splice the optical fiber.

- Optical power decreases: Check whether the fiber bend is too small and whether the connector connection is good. Replace the optical fiber if necessary.

- Water leakage from the connection box: Check whether the sealing ring and waterproof joint are aged and damaged, and replace relevant parts in time.

- Communication failure: For the monitoring connection box, check whether the communication interface connection and the working status of the sensor are normal.

- Lock failure: Regularly check and maintain the anti-theft lock of the connection box to ensure safety.

Therefore, the correct installation and regular maintenance of fiber optic splice boxes is very important. Only by doing these key tasks well can we ensure the long-term stable and reliable operation of the connection point and minimize the probability of optical fiber network failure. For some common faults, targeted troubleshooting and handling measures also need to be taken. Only by fully mastering the installation and maintenance skills of splice boxes can the safe and efficient operation of optical fiber networks be ensured.

In which fields are optical fiber splice boxes used?

Optical fiber splice boxes play an important role in information communications, data transmission and network connections in various industries, providing reliable infrastructure support for the digitalization and informatization process of modern society. Fiber optic splice boxes are widely used in many fields, some of the main fields include the following:

Metropolitan area network (MAN)

- Metropolitan area networks usually use trunk optical cables, which require optical fiber connections and branches at multiple nodes.

- Outdoor buried fiber optic splice boxes play a key role in this scenario, as they can effectively withstand harsh environmental factors.

- The sealing and waterproof performance of the splice box ensures the reliability and stability of trunk optical fiber connections and reduces interruptions caused by environmental damage.

- Large-capacity splicing boxes can also meet the demand for large-scale optical fiber splicing for metropolitan area network backbone transmission.

Data center applications

- Dense optical fiber cabling is used inside the data center, requiring a large number of optical fiber connection points.

- Cabinet-mounted splice boxes are very suitable for this scenario. They conform to standard cabinet sizes and facilitate centralized management.

- Complete optical fiber management functions, such as bending radius control, identification system, etc., greatly simplify the optical fiber cabling work in the data center.

- The monitoring function can monitor the working status of each connection point in real time, which is helpful for quickly locating and repairing faults.

FTTH (fiber to the home) applications

- FTTH networks require a large number of branch access points, and branch fiber optic splice boxes are very suitable.

- This type of splice box has a relatively small capacity, but has flexible on-site installation and maintenance features.

- They are usually installed in small computer rooms on the roadside or near routers to provide users with nearby access services.

- The protective performance of the branch splice box has also been enhanced, reliably protecting the optical fiber connection on the user side.

In summary, the application of fiber optic splice boxes in fiber optic networks is crucial, it can not only ensure reliable transmission of optical fiber signals, but also improve the stability and maintainability of the network to meet network needs in different scenarios.

Summary

The optical fiber splice box is undoubtedly an essential component in the construction and maintenance of optical fiber networks. It can provide reliable protection and management for fiber fusion splicing connection points, ensuring the stability and reliability of fiber transmission. Whether it is a metropolitan area network, data center or FTTH application scenario, fiber optic connection boxes play a key role.

We provide a variety of types and specifications of fiber optic splice box products, covering different installation requirements such as indoor wall-mounted and outdoor buried, and ensure that the products meet industry standards in terms of materials and sealing. If you need to consult about fiber optic splice boxes during the construction or maintenance of fiber optic networks, please feel free to contact us.

Fiber Splice Case FAQ

A fiber splice case is a protective enclosure used to house and protect fiber optic cable splices. It provides a secure and weatherproof environment for the spliced fibers.

Protect the fiber optic splices from environmental factors like moisture, dust, and physical damage

Provide strain relief and secure the incoming and outgoing fiber optic cables

Allow easy access for splicing, maintenance, and troubleshooting

Fiber splice cases are available in various sizes and configurations, such as inline splice cases, branch splice cases, and end-of-line splice cases, to accommodate different fiber optic cable installations.

Fiber splice cases are often constructed using weather-resistant materials like thermoplastic, fiberglass, or metal, depending on the application and environmental factors.

Fiber splice cases are typically installed along the fiber optic cable route, at locations where splices are required. They may be buried, mounted on poles, or placed in underground vaults, depending on the installation environment.

Important factors include the number of fiber splices it can accommodate, cable entry and exit points, sealing mechanisms, accessibility, and compatibility with the specific fiber optic cable types and diameters.

Fiber optic cables are carefully routed and secured within the splice case using cable clamps, organizers, and slack management features to ensure proper strain relief and protection of the splices.

Regular inspection, cleaning, and proper sealing are essential to ensure the continued protection of the fiber optic splices. Replacement of worn or damaged components may be necessary over time.

Outdoor splice cases are typically designed to provide a higher level of environmental protection, such as resistance to water, temperature extremes, and UV exposure, compared to indoor splice cases.

In some cases, fiber splice cases can be reused or relocated, depending on the design and the specific requirements of the new installation. However, caution must be taken to ensure the integrity of the splice and cable routing.