Fiber optic connectors undoubtedly play an important role in optical networks. This article will focus on how to connect fiber optic cables to SC connectors. We will first outline the basic structure and classification of fiber optic cables and introduce common fiber optic connector types, including SC, FC, LC, etc. Next, we will explain in detail the technical characteristics of SC fiber optic connectors and analyze their typical applications in different network environments.

We will demonstrate the specific process of fixing the optical fiber to the SC connector and completing the docking, explain the matters that need to be paid attention to when docking the optical fiber with the SC connector, and introduce the best practices to ensure stable and reliable fiber optic connections. In addition, we will describe the standardized method for testing the quality of fiber optic connections and provide suggestions for regular inspection and maintenance of fiber optic connections.

Basic knowledge of fiber optic cables and connectors

Let me give you a brief introduction to the basic knowledge of fiber optic cables and connectors.

Basic structure and classification of fiber optic cables:

(1) Construction

- Fiber optic cables are composed of optical fibers, buffer layers, reinforcement layers, and outer sheaths.

- Optical fiber is the core part of optical signal transmission and is made of glass or plastic materials.

- The buffer layer, reinforcement layer and outer sheath protect the optical fiber and enhance its mechanical strength.

(2) Classification

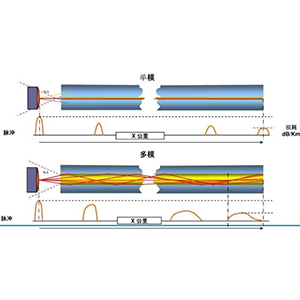

- Optical fiber cables can be divided into two categories: single-mode optical fiber and multi-mode optical fiber.

- Single-mode optical fiber has a smaller core diameter and only allows one optical mode to be transmitted, which is suitable for long-distance transmission.

- Multi-mode optical fiber has a larger core diameter and allows multiple optical modes to propagate, which is suitable for short-distance transmission.

- Depending on the materials of the optical fiber and the buffer layer, it can also be divided into quartz optical fiber and plastic optical fiber.

Common types of optical fiber connectors:

(1) SC connector

- It adopts a push-pull design, is larger in size, and is widely used. It is commonly used in telecommunication networks.

(2) FC connector

- Spiral interface design, reusable, mainly used in telecommunications and military fields.

(3) LC connector

- Adopts RJ-45 interface design, compact size, commonly used in data centers and enterprise networks.

(4) ST connector

- Adopts BNC design, can be locked and fixed, mainly used for analog video transmission.

(5) MPO/MTP connector

- Adopts multi-channel parallel design, suitable for high-density fiber optic cabling systems.

Different types of fiber optic connectors have their own characteristics in terms of size, interface mode, and usage scenarios. When designing a network, you need to choose according to actual needs. In general, the basic structure of optical fiber cables and connector types are the basic knowledge for understanding optical fiber networks. Mastering these basic knowledge will help you better design and deploy optical fiber communication systems.

Characteristics and applications of SC optical fiber connectors

Let me introduce you in detail the technical characteristics of SC optical fiber connectors and their typical applications in different network environments.

Technical characteristics of SC optical fiber connectors:

(1) Interface design

- SC connectors adopt a push-pull interface design, which is easy to plug and unplug.

- The internal precision alignment mechanism can accurately align the optical fiber core.

(2) Optical performance

- SC connectors have good optical coupling efficiency and low optical fiber insertion loss characteristics.

- It can provide stable optical fiber connection quality and ensure the quality of optical signal transmission.

(3) Mechanical strength

- The SC connector shell is made of durable plastic material and has high mechanical strength.

- It can withstand certain external vibration and impact and is suitable for various complex environments.

(4) Dimensions

- The SC connector has a large outer dimension of approximately 20×10×40mm.

- Compared to other small connectors, the SC connector occupies a larger space.

In general, SC fiber optic connectors are widely used in various types of fiber optic communication networks due to their simple and easy-to-use interface design, excellent optical performance and good mechanical strength.

Typical applications of SC connectors in different network environments:

(1) Telecom operator network

- SC connectors are widely used in the backbone transmission network of telecom operators.

- Its stable and reliable performance is very suitable for telecommunications-grade network environments.

(2) Enterprise/campus networks

- SC connectors are also commonly used in small and medium-sized fiber optic networks such as enterprise LANs and campus networks.

- Its anti-interference ability and mechanical strength can meet the requirements of such environments.

(3) Computer rooms and data centers

- SC connectors can be used in optical fiber wiring systems inside computer rooms and data centers.

- Its large size is suitable for the application of centralized wiring racks.

(4) Industrial control networks

- The durability of SC connectors is also suitable for control networks in industrial sites.

- Its ability to withstand harsh industrial environmental conditions, such as temperature and vibration.

In short, with its excellent technical characteristics, SC fiber optic connectors are widely used in telecommunication networks, enterprise networks, data centers, and industrial control. It has become one of the classic connectors in the field of fiber optic communications.

Steps to connect fiber optic cable to SC connector

Let me introduce you in detail the specific steps to connect fiber optic cable to SC connector.

Prepare fiber optic cable and SC connector:

(1) Strip fiber optic cable

- Use a special stripping tool to carefully strip the outer sheath of the fiber optic cable.

- Expose the fiber core and protective layer, and be careful not to damage the fiber body.

(2) Cut fiber

- Use a fiber optic cleaver to cut the fiber vertically to obtain a flat fiber end face.

- Make sure the cutting length is appropriate to facilitate subsequent fixing to the SC connector.

(3) Clean the fiber end face

- Use fiber cleaning paper and alcohol to wipe the fiber end face to remove dust and stains.

- Ensure that the end face is clean and free of impurities to avoid affecting the transmission of optical signals.

(4) Prepare the SC connector

- Check whether the internal alignment mechanism of the SC connector is intact.

- If necessary, clean the inside of the SC connector with alcohol.

Fix the fiber to the SC connector and complete the docking:

(1) Insert the fiber

- Carefully insert the prepared fiber into the fiber optic jack of the SC connector.

- Pay attention to the insertion direction of the fiber and ensure that the end face is aligned with the inside of the SC connector.

(2) Fix the optical fiber

- Use a special tool to fix the optical fiber to the SC connector housing.

- You can use glue or snaps to fix the optical fiber to ensure that it does not fall off.

(3) Complete docking

- Dock the assembled SC connector with the SC connector at the other end.

- Push and pull the connector until it is fully plugged in, and ensure that the connection is secure.

(4) Check the connection quality

- Use an optical power meter or optical time domain reflectometer to check the optical loss at the connection.

- Ensure that the connection quality meets the standard requirements and the optical loss is within an acceptable range.

In short, connecting the fiber optic cable to the SC connector requires stripping, cutting, cleaning, inserting and fixing, and finally docking and checking the connection quality. This process requires certain professional operating skills to ensure the reliability of the fiber optic connection.

Correct connection method of fiber optic to SC connector

Let me introduce you in detail the matters that need to be paid attention to when correctly connecting the fiber optic to the SC connector, as well as the best practices to ensure stable and reliable fiber optic connections.

Things to pay attention to when docking the fiber optic and SC connector:

(1) Cleaning the fiber end face

- Before docking, make sure that the fiber end face is clean and dust-free.

- The fiber end face can be carefully cleaned with special cleaning paper and alcohol.

(2) Fiber insertion direction

- The fiber must be inserted into the fiber optic jack of the SC connector in the correct direction.

- Usually, the groove of the optical fiber should be aligned with the alignment protrusion inside the SC connector.

(3) Firmly fix the optical fiber

- After inserting the optical fiber into the SC connector, it must be securely fixed with a special tool.

- Be careful not to apply excessive force when fixing to avoid damaging the optical fiber.

(4) Docking alignment accuracy

- The internal alignment mechanism of the SC connector needs to be accurately aligned with the optical fiber end face.

- Push and pull slowly during docking to ensure a secure connection and minimize optical loss.

(5) Clean working environment

- During the entire optical fiber docking process, try to operate in a clean environment.

- Avoid dust or other impurities from entering the optical fiber end face and the inside of the SC connector.

Best practices to ensure stable and reliable fiber connections:

(1) Use professional tools

- Use professional fiber stripping tools, cutting knives, and cleaning paper.

- These tools can ensure that the fiber is not damaged during operation.

(2) Check the connection quality

- You can use an optical power meter or optical time domain reflectometer to measure the optical loss at the connection.

- If the optical loss is too large, you need to recheck the fiber end face and docking condition.

(3) Regular maintenance

- Fiber connections need to be regularly inspected and cleaned to ensure long-term stability.

- Especially when used in harsh environments, maintenance is even more critical.

(4) Take protective measures

- Fiber optic connectors can be protected by using devices such as sheaths or protective boxes.

- Reduce the impact of external factors on fiber optic connections and improve anti-interference capabilities.

In short, the correct connection of optical fiber to SC connectors requires attention to many factors, from end face cleaning, insertion direction, firm fixation to docking accuracy. At the same time, adopting best practices such as professional tools, regular maintenance, and protective measures can ensure the stability and reliability of fiber optic connections.

Testing and maintenance of fiber optic to SC connector connections

Let me introduce you to the standardized method for testing the quality of fiber optic to SC connector connections, as well as recommendations for regular inspection and maintenance.

Standardized method for testing the quality of fiber optic connections:

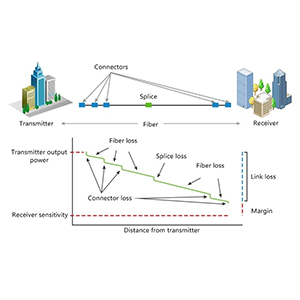

(1) Optical power test

- Use an optical power meter to measure the incident optical power and the outgoing optical power at the connection.

- Calculate the optical power loss and compare it with the manufacturer’s given indicators.

(2) Optical reflection test

- Use an optical time domain reflectometer (OTDR) to detect the optical reflection characteristics of the connection.

- Observe the reflection peak to ensure that the reflection loss at the connection is within an acceptable range.

(3) Optical fiber loss test

- Use the double-ended test method to measure the total optical fiber loss of the entire optical fiber link.

- And compare it with the theoretical value calculated from the loss coefficient of a single section of optical fiber.

(4) Optical interface inspection

- Use an optical microscope to observe the cleanliness and surface quality of the optical fiber end face.

- Ensure that the end face is free of scratches, stains and other defects and meets standard requirements.

These test methods are based on international standards and can comprehensively evaluate the quality of fiber-to-SC connector connections.

Recommendations for regular inspection and maintenance of fiber connections:

(1) Regular inspections

- Perform regular inspections of fiber links and observe the appearance of connectors.

- Check for looseness, damage, or contaminationsigns.

(2) Cleaning and maintenance

- Perform regular cleaning and maintenance on the fiber end face and the inside of the connector.

- Use professional cleaning tools and methods to avoid new damage.

(3) Performance testing

- Perform regular performance tests on the fiber link, such as optical power and optical reflection.

- Monitor changes in key parameters to identify and resolve problems in a timely manner.

(4) Environmental protection

- Take necessary environmental protection measures, such as dust covers and protective boxes.

- Reduce the impact of external factors such as dust and moisture on fiber connections.

(5) Spare parts

- Prepare a certain number of spare fiber optic connectors and related tools.

- In order to repair the fiber optic link in time in case of emergencies.

Through regular inspections, cleaning and maintenance, performance testing, environmental protection and other measures, the connection quality and reliability of fiber to SC connectors can be effectively ensured. This is crucial to ensure the normal operation of the fiber optic network.

Summary

Proper connection and maintenance of fiber to SC connectors are crucial. Our company has long been focusing on the research and development and production of optical communication equipment and its supporting products, and has rich industry experience. Our SC fiber optic connector products have reached the industry-leading level in terms of performance and reliability, and can meet your demanding needs for high-quality optical network construction.

Whether you need to deploy SC fiber optic connections in telecom operator networks, data centers, or enterprise parks, we can provide you with customized solutions. At the same time, our professional team will provide you with a full range of technical support, including on-site surveys, installation guidance, and regular maintenance. Contact us now to learn more about fiber to SC connectors.

Connect Fiber Optic Cable TO SC Connector FAQ

An SC (Subscriber Connector) is a type of fiber optic connector with a square shape and a push-pull latching mechanism.

To connect a fiber optic cable to an SC connector, you will need to clean the fiber end, insert it into the SC connector, and secure the latch.

The basic tools needed are fiber optic cleaver, fiber optic stripper, and a fiber optic connector installation tool.

The typical process involves stripping the cable jacket, cleaving the fiber, inserting the fiber into the SC connector, and crimping or gluing the connector.

Proper fiber end face preparation, connector alignment, and full engagement of the latch are crucial for a reliable SC fiber optic connection.

SC connectors are compatible with both single mode and multimode fiber optic cables, as long as the connector and cable match.

The maximum distance depends on factors like fiber type, wavelength, and connector quality, but can range from hundreds of meters to tens of kilometers.

Commonly used test methods include optical power measurement, optical return loss, and optical time domain reflectometry (OTDR).

Potential problems include dirt/contamination, improper cleaving, air gaps, and reflections caused by poor connector mating.

While possible, it’s generally not recommended to reuse an SC connector, as the termination process can damage the connector over time.