Fiber optic splitters play an important role in optical communications. This article will focus on the different types of PLC fiber optic splitters. We will first define the basic structure and working principle of the PLC splitter and explain its advantages over other splitters. Next, we will analyze the main types of PLC fiber optic splitters in depth, including the division according to different dimensions such as splitting ratio, number of cores, wavelength range, structural form, and splitting method.

We will introduce the characteristics of each type of PLC splitter and analyze their applicability in different application scenarios. Finally, we will provide suggestions for selecting PLC splitters based on actual needs and explain the key factors that need to be paid attention to in the application.

Basic Overview of PLC Fiber Optic Splitters

Basic Structure and Working Principle of PLC Splitters:

- PLC (Planar Lightwave Circuit) splitter is an optical splitter on an integrated optical chip.

- It consists of the following main parts:

- Single-mode fiber input end

- Y-type optical splitter

- Multiple single-mode fiber output ends

- Working principle:

- The single-mode optical signal at the input end enters the PLC chip and is divided into multiple optical signals by the Y-type optical splitter.

- The split optical signal is transmitted through the single-mode fiber output end.

Advantages of PLC splitter compared with other splitters:

- High integration: PLC splitter adopts integrated optical path design, which has the characteristics of small size and light weight.

- High reliability: PLC splitter does not require mechanical action, has a simple structure, and has strong resistance to vibration and environmental influence.

- Low manufacturing cost: PLC splitters use semiconductor manufacturing technology, and the cost of mass production is low.

- Stable performance: The key parameters of the PLC splitter, such as optical path uniformity and isolation, are more stable than those of other splitters.

- Wide wavelength range: PLC splitters can operate in the entire optical communication wavelength range and are compatible with various light sources.

- Strong integration: PLC splitters can be integrated with other optoelectronic devices on the same substrate, which is conducive to system integration.

In general, PLC splitters are widely used in optical communication networks due to their high integration, high reliability and low cost, and are an important optical splitting device.

Main types of PLC fiber splitters

PLC fiber splitters mainly include equal-division type (such as 1×2, 2×2), coupling type (such as 1×N, 2×N) and increase/decrease type (such as M×N). They realize the distribution and integration of optical signals through silicon-based planar waveguide circuit technology and are widely used in fiber-optic communication systems and fiber-optic sensors. These splitters are characterized by low loss, high reliability and compactness, which are of great significance to improving system performance and reducing costs.

According to the split ratio:

- PLC splitters with different split ratios such as 1×2, 1×4, and 1×8:

- 1×2 PLC splitter splits the input optical signal into two outputs. It is used for branching and combining of optical fiber networks.

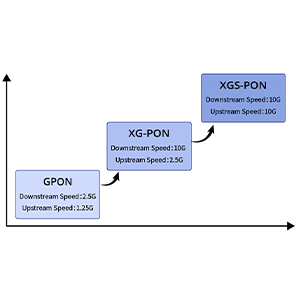

- 1×4 and 1×8 PLC splitters split the input optical signal into 4 or 8 outputs. It is used in access networks such as FTTH and PON.

- The larger the split ratio, the lower the output power, but it can meet the needs of more users. It is necessary to balance the split ratio and power consumption.

Based on the number of cores:

- Single-core PLC splitter: has only one input fiber and multiple output fibers.

- Multi-core PLC splitter: has multiple input fibers and multiple output fibers.

- Single-core PLC splitter has a simple structure and low cost, suitable for small and medium-sized networks. Multi-core PLC splitter can achieve multiplexing and is suitable for large-capacity networks.

Based on wavelength range:

- Single-wavelength PLC splitter: only works at a fixed wavelength.

- Broadband PLC splitter: can work in a wide range and is compatible with different wavelengths.

- Single-wavelength PLC splitter has a lower cost, but its application is limited. Broadband PLC splitter is more flexible and suitable for wavelength multiplexing networks.

According to the structural form:

- Plane PLC splitter: The optical paths are integrated in a single plane.

- Three-dimensional PLC splitter: The optical paths are integrated in a three-dimensional structure.

- The manufacturing process of the planar PLC splitter is relatively simple and the cost is relatively low. The performance index of the three-dimensional PLC splitter is better, but the manufacturing complexity is higher.

According to the branching method:

- Branch type PLC splitter: It is realized by Y-type splitting.

- Coupled type PLC splitter: It is realized by optical coupling.

- The branch type PLC splitter has a simple structure, but the isolation is low. The coupled type PLC splitter has high isolation, but the structure is complex.

In general, there are many types of PLC splitters, and designers need to choose the right one according to specific application requirements.

Selection and application considerations of different types of PLC splitters

When choosing different types of PLC splitters, you need to consider their input/output points, communication interface, processing speed, and programming flexibility. The functional requirements of the splitter should be determined according to the specific application scenario to ensure the compatibility and stability of the device and system. In addition, attention should be paid to the brand reputation and after-sales service of the splitter to ensure long-term reliability and maintenance convenience.

Suggestions for selecting PLC splitters:

Based on the split ratio:

- For small-scale networks, such as homes or small businesses, 1×2 or 1×4 PLC splitters can be selected.

- Large-scale networks, such as FTTH, PON and other access networks, should use 1×8 or 1×16 high split ratio PLC splitters.

According to the number of cores:

- Single-core PLC splitters are suitable for small and medium-sized networks, with low cost and relatively simple installation and maintenance.

- Multi-core PLC splitters are suitable for large-capacity networks and can achieve multiplexing, but the cost and complexity are high.

According to the wavelength range:

- If the network uses a single wavelength, a low-cost single-wavelength PLC splitter can be selected.

- If you need to support multiple wavelengths, you should use a broadband PLC splitter.

Based on the structural form:

- Planar PLC splitters are suitable for cost-sensitive applications, such as access networks.

- Three-dimensional PLC splitters are suitable for applications that require higher performance, such as trunk networks.

Based on the branching method:

- Branch-type PLC splitters are suitable for relatively low-cost applications.

- Coupled-type PLC splitters are suitable for applications that require better isolation.

Precautions in application:

- Optical input power: Make sure that the input power is within the design range of the PLC splitter to avoid optical damage.

- Optical power balance: The optical power at different output ends must be balanced to avoid performance degradation due to power imbalance.

- Temperature stability: The performance of the PLC splitter is easily affected by the ambient temperature, and temperature control measures need to be taken.

- Light reflection and isolation: High reflection and low isolation will cause signal interference and need to be strictly controlled.

- Reliability and life: The PLC splitter must meet the reliability and service life requirements of long-term operation.

In short, the selection of PLC splitters needs to weigh factors such as network requirements and cost budgets, and pay attention to key technical indicators to ensure that application requirements are met.

Summary

PLC fiber splitters are key components for building high-performance optical communication networks. Our company has long focused on the research and development and production of PLC technology and has rich experience in the application of PLC splitters. We provide various high-performance PLC splitter products, including different splitting ratios, core numbers, wavelength ranges, structural forms and splitting methods, which can be widely used in access networks, trunk transmission, data centers and other fields. Our PLC splitters adopt advanced manufacturing processes, have excellent optical performance and reliability, and can effectively meet your specific needs.

At the same time, our engineering team will provide you with professional selection guidance and integration services to ensure that the PLC splitter performs best in actual applications. Contact us now to learn more. We will do our best to provide you with the best quality products and solutions.

PLC Splitters FAQ

A PLC (Planar Lightwave Circuit) splitter is an optical device used to divide a single optical signal into multiple outputs with high precision and low loss, utilizing planar lightwave circuit technology.

A PLC splitter works by using a planar waveguide technology to route light signals. The waveguide is etched into a flat substrate, allowing for the even distribution of the optical signal to multiple output fibers.

Advantages include low insertion loss, high splitting accuracy, uniform signal distribution, and stability over a wide range of wavelengths and temperatures.

Common types include 1×2, 1×4, 1×8, 1×16, and 1×32 splitters, referring to the number of output fibers. There are also 2×2, 2×4, and 2×8 configurations for applications requiring multiple inputs and outputs.

Typical specifications include insertion loss, splitting ratio uniformity, wavelength range, and the physical size of the splitter module. Insertion loss is usually around 0.1 to 0.3 dB per split.

Insertion loss measures the amount of signal power lost when passing through the splitter. It is crucial because lower insertion loss indicates better signal integrity and system performance.

PLC splitters use integrated planar waveguides and offer better uniformity and lower insertion loss compared to FBT (Fused Biconic Taper) splitters, which use fused and tapered fibers and generally have higher insertion loss.

Yes, PLC splitters can be used outdoors if housed in appropriate enclosures to protect them from environmental factors such as moisture, dust, and temperature extremes.

PLC splitters are used in telecommunications networks, data centers, fiber-to-the-home (FTTH) networks, and other optical communication systems to distribute optical signals to multiple endpoints.

PLC splitters should be handled carefully to avoid bending or stressing the fibers. They should be installed in clean environments and properly aligned to ensure optimal performance and longevity.