Welcome to read this article. I will introduce you to the definition, basic principles and applications of APC (Angled Physical Contact) optical fiber in different fields. We will delve into the design principles and features of APC connectors to help you fully understand this innovative technology.

APC optical fiber is widely used in fields such as optical fiber communication networks and optical fiber sensing technology. We will focus on the application scenarios and advantages of APC optical fiber in optical fiber communication networks, as well as its application in optical fiber sensing technology, such as temperature, pressure and strain sensors.

In addition, we will also explain the lower reflection loss (RL) characteristics of APC optical fiber compared to PC (Physical Contact) connectors, as well as the methods and advantages of reducing pigtail echo in APC optical fiber design.

When using APC fiber optics, proper installation and connections are very important. Therefore, we will provide installation and connection suggestions for APC optical fiber, and introduce the key points of cleaning and maintenance to ensure the reliability of signal transmission.

Understanding APC fiber optic standards and specifications is critical to ensuring quality and reliability. Therefore, we will introduce the international standards and specifications related to APC fiber optics and explore the methods and requirements for connection reliability testing.

Finally, we will look at the future development trends of APC optical fiber, including its application prospects in high-density optical fiber connections and all-optical networks. As technology continues to advance, APC fiber optics will continue to play an important role in meeting growing demand.

Introduction to APC optical fiber

Definition and rationale:

APC (Angled Physical Contact) fiber is a fiber optic connector interface type, which is characterized by the fiber bevel angle on the connector end face. Compared with traditional PC (Physical Contact) optical fiber connectors, the bevel angle of the APC connector can reduce reflection and return loss and improve the quality and performance of optical signal transmission.

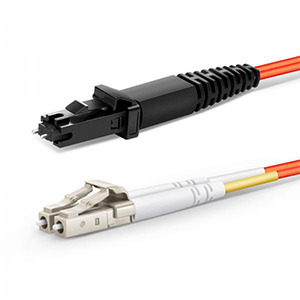

APC connector:

The APC connector is a specially designed fiber optic connector whose main feature is the fiber bevel angle on the connector end face. The following are the design principles and characteristics of APC connectors:

-

Bevel angle: There is a bevel angle between the fiber end face of the APC connector and the normal line, usually 8 degrees. This bevel angle causes the end face of the connector to form a small plane at a certain angle to the fiber transmission direction, thereby reducing the reflection of the optical signal.

-

Reflection loss: Due to the existence of the bevel angle, the reflection loss of the APC connector is low. Reflection loss refers to the energy loss caused by the reflection of optical signals from the connector interface. The bevel angle of the APC connector causes the reflected light signal to be reflected multiple times inside the connector and is eventually absorbed, reducing reflection loss.

-

Insertion loss: The insertion loss of APC connector is equivalent to that of PC connector, and there is no obvious difference in general applications. Insertion loss refers to the energy loss caused by optical signals passing through the connector interface.

-

Compatibility: The APC connector is very similar to the traditional PC connector in appearance, but due to the different bevel angles, the APC connector and the PC connector are not directly compatible. When using APC connectors, you need to ensure that both ends of the connection are APC connectors to ensure consistent performance and quality.

Due to its low reflection loss and high optical signal quality, APC connectors are widely used in fiber optic applications that require lower reflection loss and higher performance, such as fiber optic communications, data centers, active optical networks, etc.

Application fields of APC optical fiber

Optical fiber communication network:

APC optical fiber has a wide range of application scenarios and advantages in optical fiber communication networks, including the following aspects:

-

Fiber optic transmission system: In the fiber optic transmission system, APC fiber is used to connect fiber optic transceivers, fiber optic switches, fiber optic amplifiers and other equipment. Due to the low reflection loss characteristics of the APC connector, it can provide higher signal quality and transmission performance, ensuring the stability and reliability of optical signals during transmission.

-

Optical fiber distributed sensing: APC optical fiber can also be used in optical fiber distributed sensing systems, such as fiber Bragg grating sensors (FBG). Utilizing the low reflection loss characteristics of the APC connector, the optical signal reflection caused by the connector can be reduced and the sensitivity and accuracy of the FBG sensor can be improved.

-

Fiber-to-the-home (FTTH) network: In fiber-to-the-home network, APC optical fiber is used to connect optical fiber terminal boxes and user terminal equipment. The low reflection loss of APC connectors can reduce signal reflection and interference, providing more stable and high-quality fiber access services.

Fiber optic sensing technology:

APC optical fiber is also used in fiber optic sensing technology, especially in fiber optic sensors. Here are some examples of APC fiber applications in fiber optic sensing technology:

-

Temperature sensor: By introducing temperature-sensitive materials or fiber Bragg gratings (FBG) into APC optical fibers, optical fiber temperature sensors can be realized. By measuring temperature changes in optical fibers, the temperature environment can be monitored and controlled.

-

Pressure sensor: By introducing pressure-sensitive materials or fiber Bragg gratings (FBG) into APC optical fibers, fiber optic pressure sensors can be realized. By measuring pressure changes in optical fibers, pressure signals can be monitored and measured.

-

Strain sensor: Fiber optic strain sensors can be realized by introducing strain-sensitive materials or fiber Bragg gratings (FBG) into APC optical fibers. By measuring strain changes in optical fibers, the deformation and strain of objects can be monitored and measured.

The application fields of these optical fiber sensing technologies include structural health monitoring, industrial automation, oil and gas pipeline monitoring, aerospace and other fields, providing accurate, reliable and real-time sensing data.

Features and advantages of APC optical fiber

Reflection loss (RL):

APC optical fiber has lower reflection loss characteristics than PC connectors. Reflection loss refers to the energy loss caused by the reflection of optical signals at the connector interface. The following are the reflection loss advantages of APC fiber optics compared to PC connectors:

-

Bevel angle design: The fiber end face design of the APC connector has a bevel angle, usually 8 degrees. This bevel angle causes the reflected light signal to be reflected multiple times inside the connector and eventually absorbed, reducing reflection loss. In contrast, PC connector end faces are cut vertically and are prone to reflections.

-

Low reflection loss: Due to the bevel angle design of the APC connector, the reflection loss can generally reach -60dB or lower, while the reflection loss of the PC connector is generally around -40dB. Lower reflection loss means less optical signal energy is reflected back to the source, thereby improving optical signal transmission quality and system performance.

Reduce pigtail echo:

APC optical fiber design uses some methods to reduce tail reflection, which is the echo caused by the reflection of optical signals between the connector and the tail fiber. Here are the methods and advantages of reducing pigtail echo:

-

Bevel angle design: The bevel angle design of the APC connector not only reduces the reflection loss on the connector end face, but also reduces the reflection between the connector and the pigtail. The bevel angle increases the angle between the reflected light and the main light when the optical signal is transmitted in the pigtail, reducing the impact of reflected echo.

-

Pigtail suppression structure: The pigtail of APC fiber usually adopts a special suppression structure, such as adding absorbing materials or adopting a light leakage structure. These structures can effectively absorb or disperse the reflected optical signals in the pigtail, reducing the impact of echoes, thereby improving the transmission quality and performance of optical signals.

Advantage:

APC optical fiber has the following advantages compared to PC connectors:

-

High-quality optical signal transmission: The low reflection loss of APC fiber and the design of reducing pigtail echo make the optical signal transmission quality higher, reduce signal attenuation and interference, and improve the reliability and performance of the system.

-

Suitable for high-performance applications: Due to its excellent optical performance, APC optical fiber is often used in applications requiring lower reflection loss and higher performance, such as optical fiber communications, data centers, active optical networks, etc.

-

Compatibility and standardization: APC connectors are very similar to traditional PC connectors in appearance, but due to different bevel angles, APC connectors and PC connectors are not directly compatible. However, there are already standardized APC connector and interface specifications on the market, ensuring compatibility and interoperability between different devices.

Precautions for using APC optical fiber

Installation and connection:

When installing and connecting APC fiber optics, here are some recommendations and steps to ensure proper connection and signal transmission:

-

Make sure the environment is suitable: Before installing and connecting APC fiber optics, make sure the working environment is dry, clean, and free from dust, grease, and other contaminants.

-

Check the fiber optic connector and interface: Before connecting, check whether the end face of the APC connector and interface is clean and there is no obvious damage or contamination. If necessary, use a pure non-woven cloth or a special fiber optic cleaning rod to clean.

-

Angle alignment and gentle insertion: When inserting the APC connector, make sure the bevel angle is aligned and insert gently until fully connected. Avoid using excessive force or sudden impacts.

-

Connection protective sleeve: After connection, use a connection protective sleeve (such as a protective cap or boot) to cover the connector end face to protect the fiber optic connector from contamination and physical damage.

Cleaning and Maintenance:

In order to ensure the signal transmission reliability of APC optical fiber, the following are some cleaning and maintenance points:

-

Regular cleaning: Clean the APC connector end face regularly to remove contaminants, dust and grease. Use special fiber optic cleaning tools and cleaners, and avoid using cotton swabs, paper towels, and other items that may leave fibers or dust behind.

-

Gentle cleaning movements: When cleaning the connector end face, use gentle rotating or wiping movements to avoid excessive pressure or scratching the connector. At the same time, avoid touching the end surface to avoid leaving fingerprints or stains.

-

Use of protective cover: When the APC connector is not connected, use a protective cover (protective cap or protective sleeve) to protect the connector end face to prevent contamination, scratches or damage.

-

Avoid bending and tension: During use and operation, avoid excessive bending or applying excessive tension to the optical fiber to prevent fiber breakage or damage.

-

Regular inspection and maintenance: Regularly check the stability and performance of APC fiber optic connections. If poor connections, signal attenuation or other abnormalities are found, repair or replace them promptly.

Please note that the above recommendations are for reference only and specific installation, connection, cleaning and maintenance operations may vary depending on the specific situation. Before performing any operation, it is recommended to refer to the relevant equipment and fiber manufacturer’s guidelines and instructions and follow the operating instructions provided by them.

APC optical fiber standards and specifications

International standards:

The main international standards organizations and specifications related to APC fiber optics include:

-

IEC (International Electrotechnical Commission): IEC is an international standardization organization in the field of electrical and electronic technology. Standards related to optical fiber communications are formulated by the IEC/TC86 Committee. The IEC 61753 series of standards covers specifications for fiber optic connectors, connector interfaces and fiber optic connection performance.

-

ITU-T (International Telecommunication Union Telecommunication Standardization Sector): ITU-T is an international organization responsible for standardization in the telecommunications field. In the field of optical fiber communications, ITU-T has released a series of relevant standards, including the G.651 to G.657 series of standards, covering optical fiber specifications, test methods and characteristic requirements.

-

TIA (Telecommunications Industry Association): TIA is the standardization organization for the U.S. telecommunications industry. Its optical fiber-related standards are formulated by the TIA TR-42 Committee. The TIA-568 series of standards specifies requirements for cabling systems within buildings, including specifications for fiber optic connectors and fiber optic media systems.

Connection reliability test:

Connection reliability testing of APC optical fiber is an important step to ensure the quality and performance of optical fiber connections. The following are common connection reliability testing methods and requirements:

-

Reflection loss test: Evaluate the reflection performance of the connector end face by measuring the reflection loss (Return Loss) at the connector interface. Use test equipment such as a light source and optical power meter to conduct a reflection loss test to ensure that the reflection loss of the APC connector is within the specified range.

-

Insertion loss test: Evaluate the transmission performance of the connector by measuring the insertion loss (Insertion Loss) when the connector is inserted. Use test equipment such as light sources and optical power meters to conduct insertion loss tests to ensure that the insertion loss of the APC connector is within the specified range.

-

Vibration and shock test: Test the mechanical reliability and connection stability of the connector by simulating the vibration and shock environment of the device during transportation and use. These tests can help evaluate a connector’s reliability in harsh environments and prevent problems such as loose or broken connections.

-

Thermal cycle test: Test the thermal expansion and contraction performance of the connector by conducting thermal cycles under different temperature conditions. This test can simulate the stability of the connector under temperature changes and evaluate the reliability of the connector in different temperature environments.

The above are some common connection reliability testing methods, but the specific testing methods and requirements may vary according to different standards and applications. When conducting connection reliability testing, it is recommended to refer to applicable standards and manufacturer’s guidelines and ensure that test equipment and methods meet the corresponding requirements.

The future development trend of APC optical fiber

High-density connections:

In the future, as data demand continues to grow, high-density fiber optic connections will become an important development trend. APC optical fiber has the following application prospects in high-density connections:

-

Fiber optic switches and data centers: Fiber optic switches and data centers need to handle large amounts of data traffic, and there is an increasing demand for high-density fiber optic connections. APC fiber’s beveled angle reflection design reduces reflection loss, making it ideal for high-density connections.

-

Fiber optic patch panels and fiber optic panels: As the designs of fiber optic patch panels and fiber optic panels become more and more compact, they need to support more connection ports and provide high-density connections in a limited space. The small size and low reflection loss of APC fiber optic connectors make them ideal for high-density connection applications.

-

5G and IoT: With the rapid development of 5G and IoT, the demand for optical fiber networks is also increasing. High-density connections are crucial to achieve fast and reliable data transmission between 5G base stations and IoT devices, and APC optical fiber can meet the requirements of high speed, low loss and stability.

All-optical network:

An all-optical network is a network architecture that uses optical fiber as the main transmission medium and has the advantages of high bandwidth, low latency, and long-distance transmission. APC optical fiber has the following development trends and application prospects in all-optical networks:

-

Optical fiber communication system: The core of the all-optical network is the optical fiber communication system, in which optical fiber connectors play a key role in connecting and transmitting optical signals. The low reflection loss and stability of APC fiber optic connectors make it the connector of choice in all-optical networks, providing high-quality optical signal transmission.

-

Fiber optic sensing applications: All-optical networks are not only used for data communications, but are also widely used in the field of fiber optic sensing. Optical fiber sensing technology can use optical fibers as sensors to measure physical quantities such as temperature, pressure, and deformation. The stability and low insertion loss characteristics of APC fiber optic connectors make them ideal for high-precision fiber optic sensing applications.

-

Optical fiber distributed network: The optical fiber distributed network in the all-optical network is a new network architecture based on optical fiber transmission and processing. The low reflection loss and high reliability of APC fiber optic connectors help improve the performance and scalability of fiber optic distributed networks and achieve high-speed, large-capacity data transmission.

With the increasing demand for data and the development of optical fiber communication technology, APC optical fiber will continue to play an important role in high-density connections and all-optical networks, and will continue to innovate and evolve in future development.

Summarize:

By reading this article, you will have a more comprehensive understanding of the definition, working principle and advantages of APC optical fiber. APC Fiber Optic provides high-quality fiber optic connections and transmission through its unique design and connector features. Correct installation, connection, cleaning and maintenance methods will ensure that you take full advantage of APC fiber optics and contribute to the successful application of fiber optic communication and sensing technology.

In the future, with the development of high-density optical fiber connections and all-optical networks, APC optical fiber will continue to innovate and develop, bringing broader application prospects to various fields. We look forward to working with you to explore and promote the development of optical fiber technology and contribute to the future communications world.