As someone who is interested in fiber optic connection technology, I am very excited to introduce to you APC (Angled Physical Contact) and UPC (Ultra Physical Contact) fiber optic connectors.

APC and UPC are two commonly used fiber optic connector types. They have different structural and design features and provide reliable fiber optic connection solutions. In this article, I will introduce you to their basic principles, characteristics and advantages, as well as their applications in communication networks and data centers.

Introduction to APC and UPC fiber optic connectors

Definition and rationale:

APC (Angled Physical Contact) and UPC (Ultra Physical Contact) are two commonly used types of optical fiber connectors. They are used to connect optical fibers and realize the transmission of optical signals. They are designed and work slightly differently.

UPC optical fiber connector adopts ultra-high physical contact method, in which the end face of the optical fiber adopts a spherical shape. This design enables closer contact between fibers, thereby reducing insertion loss and reflection loss. UPC connectors are suitable for most application scenarios, such as data communications, television transmission and computer networks.

APC fiber optic connectors adopt an oblique physical contact method, in which the end face of the optical fiber is obliquely cut and covered with an oblique angle. Such a design causes oblique reflection of the optical signal between the connectors, directing the reflected optical signal away from the main optical axis. This oblique reflection reduces reflection loss and return interference, so APC connectors are often used in applications that require lower reflection, such as fiber optic sensing and fiber optic system testing.

Structure and design:

There are some differences in structure and design between APC and UPC fiber optic connectors:

-

APC connector: The fiber end face of the APC connector is cut at an angle, usually at an angle of 8 degrees. This angled cut causes light to reflect obliquely between the connectors, reducing reflection loss and return interference. APC connectors usually have a green color code.

-

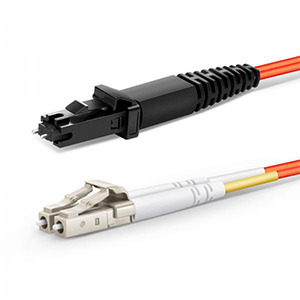

UPC connector: The fiber end face of the UPC connector is spherical in shape and has no oblique cutting. The spherical design enables better contact between fiber end faces between connectors, reducing insertion loss and reflection loss. UPC connectors usually have a blue color code.

Whether it is APC or UPC connectors, they are made using precise ceramic or metal materials to ensure good mechanical strength and stability. They typically feature LC-type connectors, but there are other types of connectors available using APC or UPC designs.

When selecting APC or UPC connectors, it needs to be determined based on specific application needs and fiber optic system requirements. APC connectors are suitable for scenarios that require lower reflection loss, while UPC connectors are suitable for most common application scenarios.

Features and advantages of APC and UPC fiber optic connectors

Return Loss:

APC connectors have lower performance in terms of reflection losses due to their angled contact surface design. When an optical signal is transmitted from an APC connector to another connector, the reflected light that occurs will be directed away from the main optical axis by the obliquely cut contact surface, thereby reducing the return of the reflected light signal. This design allows the reflection loss of APC connectors to typically reach -60dB or lower. Lower reflection losses help reduce echo interference in the system and improve overall optical signal quality.

The fiber end face of the UPC connector adopts a spherical shape and is not cut at an angle. Although the reflection loss of the UPC connector is slightly higher than that of the APC connector, it can still provide good performance. The reflection loss of UPC connectors can usually reach -50dB or less.

Plug and unplug performance:

Plug and unplug performance is one of the important indicators for evaluating fiber optic connectors, including insertion loss and recovery loss.

Insertion loss refers to the loss of optical signal power that occurs when a connector is inserted into an optical fiber. Because both APC and UPC connectors are precisely designed and manufactured, they generally have lower insertion loss. Generally speaking, the insertion loss of APC connectors is slightly higher than that of UPC connectors, but in practical applications, the insertion losses of both connectors are usually below 0.2dB, reaching high quality requirements.

Recovery loss refers to the optical signal power loss that occurs when the connector is reconnected after unplugging the optical fiber. APC connectors have lower recovery losses due to their inclined contact surface design. Recovery loss is typically -55dB or less. The recovery loss of UPC connectors is typically -45dB or less.

It should be noted that the performance of insertion loss and recovery loss is also affected by other factors, such as fiber quality, connector accuracy and usage environment.

Application scenarios of APC and UPC fiber optic connectors

Communications network:

APC and UPC fiber optic connectors are widely used in communication networks, including the following scenarios:

-

Long-distance transmission: In long-distance optical fiber transmission, signal quality and stability are crucial. APC connector has low reflection loss and echo interference due to its inclined contact surface design, and is suitable for long-distance transmission systems. They are commonly used in fiber optic backbone networks and fiber optic transmission systems to ensure reliable signal transmission and minimal signal loss.

-

Optical fiber backbone network: The optical fiber backbone network is the core of modern communication networks and carries a large amount of data transmission and communication traffic. APC connectors are widely used in various parts of fiber optic backbone networks, such as fiber optic switches, fiber optic patch cords, and optical distribution frames. Its low reflection loss and stability ensure the quality and reliability of high-speed data transmission.

data center:

APC and UPC fiber optic connectors are also widely used in data centers, including the following:

-

Server connection: Servers in data centers usually require high-speed and reliable fiber optic connections to meet the needs of large-scale data transmission. UPC connectors are commonly used for fiber optic connections between servers, providing low insertion loss and good signal transmission performance.

-

Network equipment connection: Network equipment in the data center, such as switches, routers, and storage devices, also require fast and stable fiber optic connections. APC connectors are often used for connections between these network devices to ensure the quality and stability of data transmission.

In addition, APC and UPC connectors are also widely used in other fields, such as fiber optic sensing, fiber optic testing and measurement, etc.

The choice of APC or UPC connectors should be evaluated based on specific application needs and system requirements. For scenarios that require lower reflection loss and return interference, APC connectors are more suitable. In general data transmission and communication scenarios, UPC connectors can usually provide good performance.

Compatibility of APC and UPC fiber optic connectors

Fiber type:

Both APC and UPC connectors are compatible with different types of optical fiber, including single-mode fiber and multi-mode fiber.

-

Single-mode optical fiber: Single-mode optical fiber is used for long-distance transmission and high-speed communications, where optical signals propagate in a single mode. Both APC and UPC connectors are compatible with single-mode fiber. In single-mode optical fiber applications, APC connectors are usually used in scenarios that require lower reflection loss and return interference, while UPC connectors can also provide good performance in general single-mode optical fiber systems.

-

Multimode optical fiber: Multimode optical fiber is used for short-distance transmission and low-speed data communications, where optical signals propagate in multiple modes. APC and UPC connectors are also compatible with multimode fiber. In multimode fiber applications, UPC connectors are generally the more common choice due to the relatively low reflection loss requirements.

Other connector types:

APC and UPC connectors also offer interoperability with other common connector types.

-

SC Connector: The SC connector is a commonly used fiber optic connector with a square appearance and a bidirectional insertion mechanism. Both APC and UPC connectors are compatible with SC connectors, allowing you to choose the appropriate connector type according to your needs in different application scenarios.

-

LC connector: The LC connector is a miniaturized optical fiber connector suitable for high-density optical fiber switching and data transmission environments. APC and UPC connectors are also compatible with LC connectors, providing flexible options.

-

MPO/MTP connector: MPO/MTP connector is used for high-density connection of multi-fiber optical fiber, usually used in data centers and high-speed network applications. APC and UPC connectors can also interoperate with MPO/MTP connectors to meet high-density connection needs.

It should be noted that although APC and UPC connectors can be compatible with other connector types, in actual applications, it is very important to ensure the consistency of the type and interface of the fiber optic connector to ensure good connection performance and signal transmission quality .

Selection and installation considerations for APC and UPC fiber optic connectors

Selection of fiber optic connector type (APC or UPC) should be based on the following factors:

-

Transmission distance: If long-distance fiber transmission is required, especially in single-mode fiber applications, APC connectors are usually a better choice because their inclined contact surface design can reduce reflection loss and echo interference.

-

Network performance requirements: If there are high requirements for signal quality and network performance of optical fiber connections, such as in high-speed data transmission or optical fiber backbone networks, APC connectors are also a good choice because they provide lower insertion loss and reflection loss.

-

Budget: APC connectors are generally more expensive than UPC connectors. Therefore, the available budget and the needs of the application need to be considered when making a selection.

When installing fiber optic connectors, you need to pay attention to the following:

-

Clean and protect the fiber end face: Before installing the fiber optic connector, be sure to clean and protect the fiber end face. Use appropriate fiber cleaning tools and cleaners to ensure that fiber end faces are clean and dust-free. Any contaminants or dust can cause insertion loss and degraded signal quality.

-

Correct connection method: Correct connection method is the key to ensuring connector performance. Make sure the fiber end face is aligned with the connector jack and insert gently to avoid excessive force or misalignment. Make sure the connector pins are aligned with the fiber core to avoid side bends or damage.

-

Keep the environment clean: During the installation process, it is very important to keep the environment clean and tidy. Prevent dust, dirt and impurities from entering connectors and fiber end faces. Protect unused connector end faces with connector covers or protective caps.

-

Use professional tools and techniques: For the installation and maintenance of fiber optic connectors, it is best to use professional tools and techniques. This ensures a correct and reliable connection and minimizes potential damage or performance issues.

-

Conduct a connection quality test: After the installation is completed, it is recommended to conduct a connection quality test to ensure that the connector’s performance and signal transmission quality meet the requirements. Use test equipment such as optical power meters and optical time domain reflectometers to conduct tests and verify parameters such as insertion loss and reflection loss.

Please note that if you do not have the necessary skills and experience, it is best to leave the installation of fiber optic connectors to professionals to ensure a correct and reliable installation.

Market trends of APC and UPC fiber optic connectors

Market demand for APC and UPC fiber optic connectors continues to increase. As high-speed communications, data center expansion, and fiber optic network equipment grow, so does the need for higher performance and more reliable connectors. Although UPC connectors are still very common in some applications, the demand for APC connectors is gradually increasing with the popularity of single-mode fiber optics and high-speed communications. As a result, the fiber optic connector market will continue to grow and is expected to provide more choices and innovative solutions to meet changing needs.

Summarize:

APC and UPC fiber optic connectors play an important role in the field of fiber optic communications. The APC connector achieves lower reflection loss through the design of the inclined contact surface, and is suitable for scenarios that require high reflection loss. The UPC connector provides good plugging and unplugging performance and is suitable for a variety of communication needs. They are widely used in long-distance transmission and fiber optic backbone networks in communication networks, and are also used in data centers to achieve high-speed connections for servers and network equipment.

When selecting and installing, consider application requirements and compatibility, and pay attention to proper connection methods and keeping fiber end faces clean and protected. The current market demand for APC and UPC fiber optic connectors is growing, especially in areas such as high-speed communications and data center expansion. Hopefully this article has provided you with valuable information about APC and UPC fiber optic connectors and helped you better understand and choose the appropriate fiber optic connection solution.

APC Vs UPC Connectors FAQ

The choice between APC and UPC connectors depends on the specific application and requirements. Both connectors provide reliable optical connections, but they have different polishing styles. APC connectors have an angled end-face, which reduces back-reflections and offers better return loss. UPC connectors have a flat end-face, providing low insertion loss. The better connector choice depends on factors such as network architecture, signal requirements, and compatibility with other components.

It is generally not recommended to directly connect a UPC connector to an APC connector. The different polishing styles and angles can cause high insertion loss and back-reflections, resulting in degraded optical performance. If connection between UPC and APC connectors is necessary, a mode conditioning patch cord or an adapter with built-in mode conditioning functionality should be used to mitigate the mismatch.

PC and UPC are two different polishing styles for fiber optic connectors. PC connectors have a convex end-face, while UPC connectors have a flat end-face. The key difference is that UPC connectors provide lower insertion loss and higher return loss compared to PC connectors, resulting in improved signal quality and less back-reflection.

UPC is a specific type of PC connector. While both UPC and PC connectors have a similar design with a convex end-face, UPC connectors undergo a more precise polishing process to achieve better optical performance, including lower insertion loss and higher return loss.

UPC connectors are often preferred over APC connectors in applications where low insertion loss and high return loss are critical, such as in high-speed data transmission, telecommunication networks, and CATV systems. UPC connectors provide better optical performance for most standard applications, while APC connectors are more commonly used in applications that require excellent return loss, such as fiber-to-the-home (FTTH) systems.

APC fiber connectors are primarily used in applications where low back-reflections and high return loss are crucial. They are commonly used in fiber-to-the-home (FTTH) networks, where minimizing signal degradation and maintaining optimal system performance are essential. APC connectors are also suitable for applications that require high-quality digital signals, such as digital video transmission or high-speed data communication.

UPC (Ultra Physical Contact) connectors offer several advantages:

1.Low insertion loss: UPC connectors provide low optical signal loss, minimizing the degradation of transmitted signals.

2.High return loss: UPC connectors have good return loss characteristics, reducing back-reflections and maintaining signal quality.

3.Durability: UPC connectors are designed for repeated matings and offer good resistance to wear and tear.

4.Compatibility: UPC connectors are compatible with standard PC connectors, making them widely usable in various fiber optic applications.

The SFP (Small Form-factor Pluggable) transceivers can be manufactured with either UPC or APC connectors, depending on the specific requirements and applications. The choice of UPC or APC connectors for SFP transceivers depends on the network architecture and compatibility with other components in the system.

It is generally not recommended to directly connect an SC APC connector with an SC UPC connector. The different polishing styles and angles can cause high insertion loss and back-reflections, resulting in degraded optical performance. If connection between SC APC and SC UPC connectors is necessary, a mode conditioning patch cord or an adapter with built-in mode conditioning functionality should be used to mitigate the mismatch.

Connecting an SC APC connector to an SC UPC connector directly is not recommended. The different polishing styles and angles can cause high insertion loss and back-reflections, resulting in degraded optical performance. If connection between SC APC and SC UPC connectors is necessary, a mode conditioning patch cord or an adapter with built-in mode conditioning functionality should be used to mitigate the mismatch.

In the context of fiber optics, APC refers to a specific polishing style for fiber optic connectors. It does not inherently provide any securityfeatures. The security aspect of a fiber optic network is typically implemented through encryption, authentication protocols, physical security measures, and network design considerations. APC connectors themselves do not directly contribute to the security of a network but can be used in secure network architectures to maintain signal integrity and minimize back-reflections.