Modular design is undoubtedly widely used in Cisco equipment. This article will explore the hot-swap function of Cisco modules. We will first define the basic structure and characteristics of Cisco modular equipment and briefly introduce the common types of Cisco modules. Next, we will explain the concept of hot-swap and its significance in network equipment, and explain how Cisco modules support hot-swap functions.

We will explain the hardware and software conditions that must be met for hot-swap Cisco modules and analyze the key technical indicators for hot-swap. In addition, we will list typical applications suitable for hot-swap Cisco modules and analyze the advantages of hot-swap in improving equipment availability. Finally, we will describe the correct steps and methods for hot-swap Cisco modules and provide matters and suggestions that need to be paid attention to during hot-swap.

Overview of the modular architecture of Cisco equipment

Let me give you an overview of the modular architecture of Cisco network equipment.

Basic structure and features of Cisco modular equipment:

(1) Basic structure:

- Cisco modular equipment is usually composed of the following main components:

- Chassis

- Supervisor Module

- Interface Module

- Power Module

- Cooling Module

(2) Modular features:

- Each component is an independently detachable modular design.

- Users can flexibly select and combine different types of modules according to their needs.

- This modular architecture improves the scalability and maintainability of the equipment.

(3) Advantages:

- Flexible configuration: Ability to customize device configuration to meet different application requirements.

- Convenient maintenance: Replace broken modules individually without replacing the entire device.

- Scalability: Flexible addition of interface or bandwidth modules based on business growth.

In short, Cisco’s modular network equipment has the advantages of flexible configuration, convenient maintenance and good scalability.

Common Cisco module types:

(1) Management module:

- Provides device management and control functions, such as running system software.

- Common models include Supervisor Engine, Route Processor, etc.

(2) Interface module:

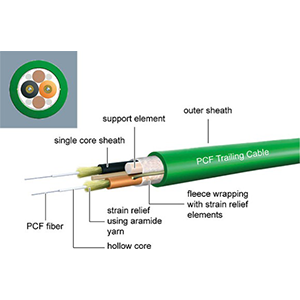

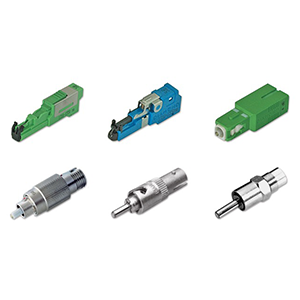

- Provides various types of network interfaces, such as Ethernet, optical fiber, serial port, etc.

- Common models include Linecards, Port Adapter, Interface Module, etc.

(3) Power module:

- Provides power supply for various components of the device.

- Optional redundant power supply can be used to improve reliability.

(4) Cooling module:

- Responsible for heat dissipation and cooling inside the device.

- Usually in the form of fan module.

Depending on different models and functional requirements, Cisco will provide a variety of modular options, and users can flexibly combine them to meet actual application needs.

Implementation of hot-swap technology in Cisco modules

Let me introduce you to the implementation of hot-swap technology in Cisco modular devices in detail.

The concept of hot-swap and its significance in network devices:

(1) The concept of hot-swapping:

- Hot-swap means that while the device is running, the module can be safely removed and inserted without interrupting the operation of the entire machine.

- This capability can greatly improve the maintainability and flexibility of the device.

(2) Significance in network devices:

- For large network devices, hot-swap technology can be used to replace faulty modules online.

- This can shorten device downtime and reduce the risk of network interruption.

- It also improves the scalability of the device, and modules can be flexibly added/replaced according to needs.

In general, hot-swap technology can greatly improve the availability and scalability of network equipment and is one of the key features of modular equipment.

How Cisco modules support hot-swap function:

(1) Hardware design:

- Cisco modules use a special connector design to support online plugging and unplugging without damaging the module or interface.

- The module also integrates a circuit protection mechanism to automatically isolate abnormal situations.

(2) Software support:

- The operating system of Cisco equipment can detect changes in the plug-in and unplug status of the module in real time.

- The system automatically identifies the newly inserted module and completes the corresponding software configuration and initialization.

- Users can add or replace modules online without affecting the operation of the device.

(3) Power management:

- Cisco modules support hot-swap and intelligent power management.

- The newly inserted module automatically obtains the required power without affecting the power supply of other modules.

(4) Compatibility guarantee:

- Cisco conducts strict compatibility testing and certification on various modules.

- Ensure that users can seamlessly replace modules online without software and hardware compatibility issues.

In general, Cisco modular devices provide comprehensive support for hot-swap functions at multiple levels, including hardware, software, and power management. This is a highlight of its modular design.

Technical requirements for hot-swap Cisco modules

Let me introduce in detail the technical requirements that need to be met to achieve hot-swap Cisco modules.

Cisco module hot-swap hardware and software requirements:

(1) Hardware requirements:

- Module connector design: Use special hot-swap connectors to support online plug-in and unplugging without damaging the interface.

- Module power design: With power hot-swap capability, the new module can automatically obtain the required power after being inserted.

- Module internal protection circuit: Integrated over-current, over-voltage and other protection circuits, which can automatically isolate abnormal situations.

(2) Software requirements:

- Operating system support: The device operating system can detect changes in the module’s plug-in status in real time.

- Instant configuration adaptation: The system can automatically identify the newly inserted module and complete the corresponding software configuration and initialization.

- Hot-swap management function: Provides online module replacement management function, which can be completed without restarting the entire machine.

Key technical indicators for hot-swap:

(1) Hot-swap time:

- The time from module insertion to commissioning should be as short as possible to reduce equipment downtime.

- The industry generally requires less than 2 minutes.

(2) Automatic module identification:

- The system can automatically detect the type and specification of the newly inserted module without manual intervention.

- Achieve plug-and-play module configuration.

(3) Status monitoring:

- The device can monitor the status of each module in real time, including plug-in and unplug, working status, etc.

- Promptly detect abnormal situations and automatically handle them.

(4) Power management:

- The newly inserted module can automatically obtain the required power without affecting the power supply of other modules.

- The power supply system has sufficient redundancy to meet various module configurations.

(5) Compatibility guarantee:

- The hardware and software compatibility between modules and between modules and devices has been fully verified.

- Ensure that users can replace modules online at will without compatibility issues.

In short, realizing the hot-swappable function of Cisco modular devices requires meeting a series of strict technical requirements at the hardware and software levels to ensure the safe and reliable plug-in and pull-out of modules.

Application scenarios of Cisco modules that support hot-swappable

Let me introduce you to the typical application scenarios suitable for using hot-swappable Cisco modules and their advantages in improving equipment availability.

Typical application scenarios suitable for using hot-swappable Cisco modules:

(1) Large network core equipment:

- Core network equipment such as routers and switches need to provide continuous and reliable services.

- Hot-swappable modules can quickly replace faulty components and reduce equipment downtime.

(2) Carrier network equipment:

- Large-scale network equipment deployed by telecom operators needs to achieve 7×24 hours of high availability.

- Hot-swappable functions can greatly improve equipment maintenance efficiency and shorten service interruption time.

(3) Data center network:

- Network equipment in the data center needs to respond quickly to changes in business needs.

- Hot-swappable modules can flexibly expand interfaces and bandwidth resources on demand.

(4) Industrial control network:

- Network equipment in the field of industrial automation needs to maintain stable operation in harsh environments.

- Hot-swap function can realize online maintenance and reduce the risk of equipment downtime.

(5) WAN router:

- WAN backbone routers need to maximize network availability.

- Hot-swap modules help to quickly locate and replace faulty components.

Advantages of hot-swap in improving equipment availability:

(1) Shorten equipment downtime:

- Faulty modules can be quickly replaced while the equipment is running without powering off the entire machine.

- Greatly shorten service interruption time during equipment maintenance.

(2) Reduce the risk of business interruption:

- Rapid replacement of faulty modules can minimize the interruption of network services.

- Improves the reliability and availability of key network equipment.

(3) Flexible online expansion:

- Interface modules can be dynamically added or replaced online according to changes in business needs.

- No need to take the entire machine offline, which improves the scalability and responsiveness of the network.

(4) Simplify the maintenance process:

- Module replacement and maintenance can be completed without downtime.

- Greatly improves the work efficiency of network administrators.

(5) Extend the service life of equipment:

- The hot-swap function reduces the risk of frequent equipment downtime due to maintenance.

- It can extend the service life of network equipment.

In summary, hot-swap technology is a highlight of Cisco modular equipment, which can effectively improve the availability and maintenance efficiency of key network equipment. This is especially important for application scenarios with strict reliability requirements.

Operation and precautions of Cisco module hot-swap

Let me introduce you in detail the correct steps and precautions for hot-swap Cisco modules in actual operation.

Correct steps and methods for hot-swap Cisco modules:

(1) Preparation:

- Make sure the device power is turned on and the whole machine is in operation.

- Check whether the module type to be hot-swapped matches the required interface.

- Take safety precautions, such as anti-static operation.

(2) Hot-swappable process:

- Slowly and carefully remove the module to be replaced from the device.

- Immediately align the new module with the empty slot and gently insert it until it is fully seated.

- Ensure that the module is fully inserted and the mechanical locking device is activated.

(3) Automatic system identification:

- The device system will automatically detect the insertion of the new module.

- The system will automatically complete the software configuration and initialization of the new module.

- After the system initialization is completed, the new module can be put into use.

(4) Verification and confirmation:

- Observe the device status indicator to confirm that the new module is working properly.

- If necessary, you can view the module information through the device management interface.

- The hot swap process is complete after confirming that the new module is working properly.

Notes and suggestions during hot swap:

(1) Operation time:

- The time interval from unplugging to plugging the module should be shortened as much as possible.

- Excessive intervals may affect the normal operation of the device.

(2) Module compatibility:

- Make sure that the new module is fully compatible with the device to avoid hardware mismatch.

- If you have any questions, consult the manufacturer or refer to relevant documents.

(3) Electrostatic protection:

- Be sure to wear an anti-static wrist strap or take other anti-static measures during operation.

- Electrostatic discharge may damage sensitive electronic components of the device.

(4) Power management:

- Pay attention to whether the new module can obtain power supply smoothly.

- If the power supply is insufficient, the module may not work properly.

(5) System check:

- Carefully observe the device status indicator to confirm that the module is working properly.

- If necessary, log in to the device management interface to further confirm the module information.

In short, following the correct hot-swap operation process and paying attention to related safety and compatibility issues are critical to ensuring the stable operation of Cisco modular devices.

Summary

Mastering Cisco module hot-swap technology will undoubtedly bring many advantages to network operation and maintenance. Our company has been committed to the sales and support services of Cisco products for a long time and has rich industry experience. Our professional team is familiar with the hot-swap operation of various Cisco modules and can provide you with comprehensive technical support.

Whether you need to use hot-swap modules on routers, switches or other Cisco devices, we can provide professional guidance and suggestions. At the same time, we also provide customers with targeted training services to help your operation and maintenance team quickly master the best practices of hot-swap. Contact us now to learn more about the details of Cisco module hot-swap function.

Cisco Modules Hot Swappable FAQ

Yes, most Cisco modules are designed to be hot swappable, meaning they can be inserted or removed from a device while it is powered on without causing disruption to the network.

Cisco switches, routers, and some other networking devices are designed to support hot-swappable modules, depending on the specific model and platform.

It’s important to follow Cisco’s guidelines for module insertion and removal, ensuring the device is in a stable operational state and that the module is compatible with the device.

Properly executed hot swapping should not affect network performance, as Cisco devices are designed to handle module insertion and removal without disrupting data flow.

While most modern Cisco modules support hot swapping, it’s essential to verify compatibility and consult the device’s documentation for specific instructions.

Cisco typically provides commands and procedures in their device documentation for safely hot swapping modules, ensuring minimal impact on network operations.

Hot-swappable modules allow for easier maintenance, upgrades, and replacements without requiring downtime, thus enhancing network availability and minimizing service interruptions.

When done according to Cisco’s guidelines, hot swapping should not cause module damage or data loss. However, improper handling or compatibility issues could potentially lead to issues.

Hot swapping may not be supported in all modules or configurations, particularly in older or specialized equipment. Always check compatibility and manufacturer recommendations.

While the principles of hot swapping apply to both SFP modules and larger line cards, the physical size and complexity of the module may influence the procedures and precautions required.