Hello everyone! Today I want to share with you a device that plays an important role in fiber optic communications – the fiber optic connector. As a key component in fiber optic communications, fiber optic connectors play an important role in achieving reliable data transmission and fiber optic interconnection. In this article, I will take you in-depth understanding of the types, characteristics and application scenarios of fiber optic connectors, so that you can better understand its importance and advantages.

Overview of optical fiber communications

Optical fiber communication is a technology that uses optical fiber as a transmission medium, converts optical signals into optical pulses in the optical fiber, and transmits and transmits information through the optical fiber. Its basic principles include the following aspects:

Light transmission characteristics: The principle of total reflection is adopted inside the optical fiber. The optical signal propagates along the core of the optical fiber. Through continuous reflection, almost no energy loss occurs.

Light modulation: Using changes in the intensity or frequency of light to carry information. A modulator is usually used to convert electrical signals into optical signals, which are then transmitted through optical fibers.

Light demodulation: Use photodetectors to convert light signals into electrical signals, and then use a demodulator to restore the original information signal.

Fiber optic connectors play a key role in fiber optic communications. They are used to connect the connection points between optical fibers to ensure reliable transmission of optical signals and stability of the connection. Connectors play the role of connecting and separating optical fibers, allowing effective communication between optical fibers.

The importance of fiber optic connectors is reflected in the following aspects:

Signal transmission quality: The quality and performance of optical fiber connectors directly affect the transmission quality of optical signals, including insertion loss (insertion loss), return loss and crosstalk and other indicators.

Reliability of connection: A good optical fiber connector can ensure a strong and stable connection and prevent the connection from loosening or disconnecting, thereby ensuring continuous signal transmission and communication reliability.

Convenience of installation and maintenance: Fiber optic connectors should have convenient installation and removal features to facilitate fiber connection and maintenance.

The factors that affect the performance of optical fiber connectors mainly include the following aspects:

End face quality: The end face quality of optical fiber connectors is crucial to the transmission quality and connection stability of optical signals. The end surfaces should be kept smooth, clean, and protected from scratches, contamination, and oxidation.

Alignment accuracy: The alignment accuracy of the connector affects the insertion loss and return loss of the connection. The higher the alignment accuracy, the lower the insertion loss and return loss.

Connection force: The connection force of the connector should be moderate. If it is too large, it may cause fiber damage or the connection is loose. If it is too small, it may cause the connection to be unstable.

In short, fiber optic connectors play an important role in fiber optic communications and have a decisive impact on signal transmission quality, connection reliability and convenient installation and maintenance. Proper selection and handling of fiber optic connectors, as well as maintaining connector quality and performance, are critical to ensuring the proper operation of fiber optic communications systems.

What are the types and structures of fiber connector

Common fiber optic connector types include SC (Subscriber Connector), LC (Lucent Connector), ST (Straight Tip) and FC (Ferrule Connector), etc. They are widely used in optical fiber communications and have different structures and working principles.

SC Connector:

- Structure: The SC connector adopts a circular shell and is fixed by insertion and rotation during connection. It has a precision ceramic or stainless steel ferrule and has a plug and socket with a push-pull locking mechanism.

- Working principle: When connecting, the ferrule on the plug rotates and enters the socket to form a reliable connection. It is commonly used in multimode fiber optic systems and is particularly suitable for dense connections.

LC Connector:

- Structure: LC connector is a small connector with a structure similar to SC connector but smaller in size. It has a round housing with a push-pull locking mechanism and uses a ceramic ferrule.

- Working principle: When connecting, the LC connector realizes the connection through the push-pull locking mechanism of the plug and socket. Due to its small size and low insertion loss characteristics, LC connectors are widely used in high-density and high-speed fiber optic communication systems.

ST Connector:

- Structure: The ST connector adopts a circular shell and uses a rotation locking mechanism to fix it when connected. It has a round ceramic ferrule with a metal sleeve.

- Working principle: When connecting, the ferrule on the plug rotates and enters the socket, and is then fixed by the rotation locking mechanism. ST connectors are commonly used in multimode fiber optic systems and data communications applications.

FC Connector:

- Structure: The FC connector has a circular shell and uses a thread locking mechanism when connecting. It uses a ceramic ferrule and has a metal sleeve.

- Working principle: By rotating the threads on the plug and the threads on the socket, the plug and socket are threaded together to achieve a stable connection. FC connectors are commonly used in single-mode fiber optic systems and test and measurement applications.

The precise alignment and stable performance of fiber optic connectors are key to ensuring optical signal transmission quality and connection stability. The construction of the connector and the locking mechanism are designed for a reliable connection. Precise alignment is key to ensuring optical signal transmission between the ferrule and socket, so the connector must be manufactured and installed to ensure accurate alignment of the ferrule and socket. Any misalignment between ferrule and receptacle can cause insertion loss, return loss, and signal attenuation.

In addition, the stability of the connector is also very important. A stable connection prevents the optical fiber from loosening or disconnecting, ensuring reliable transmission over a long period of time. Therefore, during the design and use of connectors, special attention should be paid to the locking mechanism and fixation method of the connector to ensure the stability and firmness of the connection.

What are the characteristics and advantages of fiber connector

Fiber optic connectors have the following unique features and advantages compared to other connection methods:

High bandwidth: Fiber optic connectors can support high-bandwidth optical signal transmission. Since optical signals have a higher frequency range, fiber optic connectors can achieve high-speed data transmission and are suitable for application scenarios that require large amounts of data transmission.

Low insertion loss: The design and manufacturing process of fiber optic connectors are carefully controlled, and the connection between the ferrule and the socket is very precise. Therefore, fiber optic connectors typically have low insertion loss, minimizing energy loss during signal transmission.

Low return loss: Return loss refers to the loss of the signal reflected back to the light source inside the connector. Through precise design and manufacturing, fiber optic connectors can effectively reduce return loss and ensure stable signal transmission and minimal signal attenuation.

High reliability: The connection of optical fiber connectors is stable and reliable, and can resist mechanical vibration and interference from the external environment. The connector’s locking mechanism and fixation ensure a strong connection, allowing it to remain stable over time and under harsh conditions.

High density and small size: Fiber optic connectors usually adopt miniaturized designs, such as LC connectors, which are smaller in size and suitable for high-density fiber optic connections. This makes it possible to connect a large number of optical fibers in a limited space.

Optical fiber connectors have important application advantages in high-speed data transmission and long-distance communications:

High-speed data transmission: Fiber optic connectors can support high-speed data transmission and are suitable for applications requiring large bandwidth and high-speed data transmission, such as data centers, computer networks and broadband access.

Long-distance communication: Since the transmission loss of optical signals in optical fibers is small, fiber-optic connectors can provide reliable signal transmission in long-distance communications. This makes optical fiber connectors an important part of optical fiber communication systems and are widely used in long-distance communication fields such as telecommunications networks, wide area networks, and metropolitan area networks.

Anti-interference performance: Optical fiber connectors can effectively resist electromagnetic interference and radio frequency interference. Since the transmission of optical signals is not affected by external electromagnetic fields, it can provide a more stable and reliable communication environment.

So optical fiber connectors have become an indispensable key component in modern optical fiber communication systems with their characteristics and advantages such as high bandwidth, low insertion loss, low return loss, high reliability, high density and small size. Plays an important role in data transmission and long-distance communications.

What are the application scenarios of fiber connector

Fiber optic connectors are widely used in various fields. The following are some application cases of fiber optic connectors in different fields:

Telecom sector:

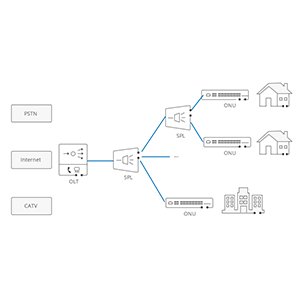

- Optical fiber communication network: Fiber optic connectors are widely used in fiber optic communication networks, including fiber optic backbone networks, fiber optic access networks, and fiber optic to the home. They are used to connect fiber jumpers, fiber distribution racks, fiber terminal equipment, etc. to achieve high-speed and stable signal transmission.

- Optical fiber sensing network: Fiber optic connectors are also used in fiber optic sensing networks to connect sensors to optical fibers to achieve high-precision monitoring and measurement of physical quantities such as temperature, pressure, and deformation.

Data Center Area:

- Data transmission: Fiber optic connectors are often used between servers, storage devices and network devices in data centers to achieve high-speed data transmission. Fiber optic connectors can meet the bandwidth and speed requirements of data centers and support fast and reliable data transmission.

- Fiber optic patch cord connection: Equipment in data centers are often connected using fiber optic patch cords and fiber optic patch panels. Fiber optic connectors are used to connect patch cords and patch cords to achieve high-performance communication between devices.

Radio and television field:

- Signal transmission: The broadcast and television industry uses fiber optic connectors to transmit video, audio and data signals to different devices and terminals. They are used to connect broadcast cameras, mixers, broadcast transmission equipment, etc. to ensure stable signal transmission and high-quality audio and video playback.

- Optical fiber distribution system: Optical fiber connectors are also used in fiber optic distribution systems in the radio and television industry to transmit signals from the center to different branch points to achieve signal distribution and expansion.

Fiber optic connectors play an important role in network expansion and system upgrades:

- Network expansion: As network demands grow, fiber optic connectors can support high bandwidth and long-distance transmission, providing reliable connection solutions for network expansion. Network capacity and coverage can be easily expanded by adding fiber optic connectors.

- System upgrade: When upgrading existing systems, fiber optic connectors can be used to connect fiber optic links between new and old equipment to achieve interconnection and compatibility between old and new equipment. The flexibility and reliability of fiber optic connectors make system upgrades easier and more efficient.

So fiber optic connectors are widely used in telecommunications, data centers, radio and television and other fields. Whether in high-speed data transmission, signal transmission or network expansion and system upgrades, optical fiber connectors play an important role, providing stable and high-performance optical fiber connection solutions for various industries.

How to correctly install and maintain fiber connector

The installation and maintenance of fiber optic connectors requires following some key steps and precautions to ensure connection quality and stability, and to avoid potential failures and damage. Here are some points to note:

Installation notes:

Clean the work area: Before installing fiber optic connectors, make sure the work area is clean and free of dust, debris, and other contaminants. Try to avoid exposing fiber optic connectors to dust and dirt.

Standard operation: Install the connector according to the installation instructions and standard operations. Ensure that the appropriate type of connector is correctly selected and installed, and that the correct tools and equipment are used for operation.

Adjust the connector core: During the installation process, make sure that the fiber core of the fiber optic connector is aligned with the corresponding fiber core. For connectors with higher requirements for precise alignment (such as LC and SC connectors), a microscope or fiber inspection tool can be used to assist alignment.

Do not bend the fiber too much: Do not bend the fiber too much near the connector to avoid damaging the fiber or causing signal attenuation. Make sure the fiber maintains a proper bend radius and avoids excessive tension.

Maintenance precautions:

Clean connectors regularly: Clean fiber optic connectors regularly to remove dirt and dust. Use appropriate fiber cleaning tools and solutions for cleaning, and avoid using substances that may damage the fiber surface.

Prevent mechanical damage: Protect the connector from mechanical damage and avoid collision, squeezing or pulling of the connector. Make sure the connector is in the correct socket and protective cover to prevent foreign objects from entering the connector.

Prevent lightFiber Stretch: Avoid excessive stretching or bending of fiber near connectors. Use appropriate fiber management equipment and patch panels to maintain proper fiber tension and routing.

FAQs and Troubleshooting:

Increased insertion loss: If insertion loss increases, it may be caused by contaminated, damaged, or loose connectors. First, try cleaning the connector and reconnecting it. If the problem persists, the connector may need to be replaced.

Increased return loss: Increased return loss can be caused by poor alignment, damage, or loose connectors. Check connector alignment and reconnect. If necessary, replace the connector.

Fiber optic breakage: The fiber optic cable near the fiber optic connector may break. Check the optical fiber for damage and repair or replace it if necessary.

Unstable connection: An unstable connection may be caused by a connector that is not plugged in correctly or a damaged connector. Make sure the connector is plugged in correctly and check the physical condition of the connector.

Proper handling and protection of fiber optic connectors is critical to help ensure connection quality and reliability. Regular cleaning and maintenance, following operating practices, and taking care to avoid problems such as mechanical damage and overstretching can improve the life and performance of fiber optic connectors. When problems arise, troubleshoot on a case-by-case basis, including cleaning the connector, reconnecting, replacing the connector, or repairing the fiber.

Summary

As a key link in optical fiber communications, optical fiber connectors demonstrate outstanding performance in various fields with their precise alignment and stable performance. Whether you are in telecommunications, data centers or broadcast television, fiber optic connectors enable high bandwidth and low insertion loss data transmission.

We provide various types of fiber optic connectors, such as SC, LC, ST and FC, etc., to meet different needs and application scenarios. If you have more questions about fiber optic connectors or need more details, please feel free to contact us. Let us build a high-speed, reliable optical fiber network together to meet the growing demand for data transmission!

Fiber Connector FAQ

A fiber connector is a device used to join or terminate fiber optic cables. It provides a secure and reliable connection for transmitting optical signals between fibers.

The common types of fiber connectors include SC (Subscriber Connector), LC (Lucent Connector), ST (Straight Tip), FC (Ferrule Connector), and MPO/MTP (Multi-Fiber Push-On/Pull-Off). Each type has its own design and application-specific characteristics.

Single-mode fiber connectors are designed for use with single-mode fibers, which have a smaller core size and are used for long-distance transmission. Multimode fiber connectors, on the other hand, are used with multimode fibers that have a larger core size and are typically used for shorter distances.

Fiber connectors work by aligning the fiber cores of two cables or devices, ensuring that light signals can pass from one fiber to another with minimal loss and reflection. They often use a combination of ceramic ferrules, alignment sleeves, and latching mechanisms to secure the connection.

Some factors to consider when selecting a fiber connector include the fiber type (single-mode or multimode), the application requirements (data rate, distance, environment), the connector compatibility with other equipment, and the ease of installation.

In some cases, different types of fiber connectors can be mated together using hybrid adapters. These adapters provide a compatible interface between two different connector types, allowing them to be connected.

Yes, fiber connectors can be field-installed using termination kits and appropriate tools. However, proper training and expertise are required to ensure accurate and reliable terminations.

The typical insertion loss of a fiber connector is generally specified by the manufacturer and depends on factors such as connector type, quality, and the mating process. It is commonly expressed in decibels (dB) and should be within acceptable limits for the specific application.

Some fiber connectors, such as SC and LC connectors, are generally considered reusable. They can be disconnected, inspected, and reconnected multiple times without significant loss or damage. However, it is important to follow proper handling and maintenance procedures to ensure their longevity.

Cleaning fiber connectors is crucial for maintaining optimal performance. Best practices include using lint-free cleaning tools, isopropyl alcohol or specialized cleaning solutions, and proper techniques such as wiping in a straight motion. It is important to avoid touching the cleaned surface of the connector.