Fiber couplers play an important role in fiber optic networks. This article will focus on how to properly clean fiber couplers. We first define the role and principle of fiber couplers and analyze the key factors that affect their performance. Next, we describe the contaminants that are easily accumulated at fiber interfaces and explain the impact of contamination on optical signal transmission.

Then, we detail the standard operations for cleaning fiber interfaces and provide tips and precautions for cleaning couplers. Finally, we analyze the cleaning methods of different types of fiber couplers and explain how to deal with special scenarios to provide users with comprehensive guidance.

What is a fiber coupler

A fiber coupler is a device used to connect and distribute optical signals and is commonly used in optical communication systems. It achieves signal transmission between different optical fibers by effectively coupling the input optical signal into multiple optical fibers. There are different types of fiber couplers, including splitters and combiners, which are suitable for various application scenarios such as fiber to the home (FTTH) and optical networks. They are designed to minimize signal loss and ensure efficient optical signal transmission.

1. Function and principle of fiber coupler:

Fiber coupler is a passive optical device used to connect or distribute fiber signals. Its main functions include:

- Connecting optical fibers:

- Physically connecting two optical fibers together to achieve optical signal transmission.

- Distributing optical signals:

- Distributing input optical signals to multiple output optical fibers.

- Merging optical signals:

- Merging multiple optical signals to the same output optical fiber.

The working principle of the fiber coupler is based on the principle of optical coupling and propagation, and uses the law of light wave propagation and reflection between different media to achieve the distribution or merging of optical signals.

2. Key factors affecting the performance of the coupler:

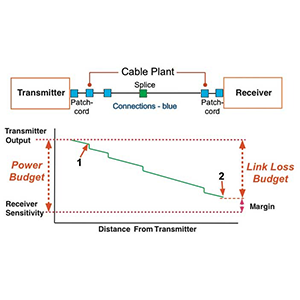

The key factors affecting the performance of the fiber coupler mainly include:

- Interface pollution:

- Dust, grease and other pollution at the coupler interface will seriously affect the coupling efficiency of the optical signal.

- Fiber alignment accuracy:

- The alignment accuracy of the fiber end face directly determines the insertion loss of the coupler.

- Polarization dependence:

- Different polarization states of optical signals will produce different transmission losses in the coupler.

- Temperature and humidity:

- Changes in ambient temperature and humidity will cause thermal expansion and contraction inside the coupler, affecting its performance.

- Manufacturing process:

- The manufacturing process level of the coupler will also have a certain impact on its optical performance.

Therefore, in practical applications, it is necessary to pay attention to these key factors and take effective measures to ensure that the fiber coupler can perform at its best performance. In short, the fiber coupler is an indispensable and important device in the optical fiber communication system, and its role and performance influencing factors deserve attention and analysis.

Common contamination problems of fiber couplers

Common contamination problems of fiber couplers mainly include dust, oil and fingerprints, which can affect the transmission efficiency of optical signals and cause signal loss or distortion. Contamination may occur on the fiber end faces and connectors, which need to be cleaned regularly to ensure performance. Using special cleaning tools and solvents can effectively remove contaminants. In addition, keeping the environment clean and proper operating specifications can also help reduce contamination problems and ensure the stability and reliability of fiber optic communications.

1. Common contamination problems of fiber interfaces:

The fiber interfaces of fiber couplers are prone to accumulate the following types of contaminants:

- Dust:

- Particles such as dust and sand floating in the environment will adhere to the fiber end faces.

- Grease:

- Organic substances such as human skin fat and fingerprint oil will be contaminated on the interface surface.

- Scratches:

- Cleaning tools or improper contact will leave fine scratches on the fiber end face.

- Others:

- Chemical solvents, water vapor, etc. may also cause pollution.

The presence of these pollutants will seriously affect the optical properties of the fiber interface.

2. Impact of pollution on optical signal transmission:

Pollution of optical fiber interface will have the following adverse effects on the transmission of optical signal:

- Increase of optical loss:

- Pollution will increase the scattering and absorption of optical signal at the interface, resulting in increased optical loss.

- Increase of reflection:

- Pollution will change the reflectivity of the interface, causing stronger reflection signal.

- Increase of interference:

- Increase of reflection signal will cause more serious interference and signal quality degradation.

- Reduced coupling efficiency:

- Contaminants will reduce the contact of the fiber end face and weaken the coupling efficiency of the optical signal.

Severe interface contamination will seriously affect the performance and stability of the entire optical fiber communication system. Therefore, it is very important to properly maintain and clean the interface of the fiber coupler, which is the key to ensuring the quality of optical signal transmission.

Fiber coupler cleaning steps

The cleaning steps of the fiber coupler include: First, use a dedicated fiber cleaning tool, such as a cleaning stick or cleaning paper, to gently wipe the fiber end face to ensure that dust and dirt are removed. Secondly, use an appropriate cleaning solvent spray to lightly wet the cleaning material, and then wipe the end face again to remove oil and fingerprints. Finally, make sure to wipe with a clean dust-free cloth after cleaning to avoid residue. After cleaning, check the connection quality to ensure stable signal transmission.

1. Standard cleaning operation of optical fiber interface:

To clean the interface of optical fiber coupler, follow the standard steps below:

(1) Prepare cleaning supplies:

- Dust-free paper or dust-free cotton swab

- Fiber optic interface cleaner (such as isopropyl alcohol)

(2) Check before cleaning:

- Visually check whether the interface is obviously contaminated

- Use magnifying glass and other tools to check carefully

(3) First wipe:

- Use cleaning paper or cotton swab to apply a small amount of cleaning agent

- Gently wipe the interface surface to remove visible dirt

(4) Secondary wiping:

- Use new cleaning paper or cotton swab to wipe repeatedly

- Ensure that the interface surface is clean and free of contamination

(5) Final inspection confirmation:

- Visually check whether the interface is clean again

- Use a magnifying glass to check if necessary

Be gentle and careful during the entire cleaning process to avoid any damage to the interface.

2. Tips and precautions for cleaning:

When cleaning the fiber coupler interface, pay attention to the following points:

- Maintain a clean environment:

- Perform cleaning operations in a clean environment to reduce secondary contamination.

- Avoid repeated contamination:

- When using cleaning paper or cotton swabs, only wipe once and then discard.

- Control the amount of cleaning solution:

- The amount of cleaning agent should be moderate, too much will easily cause residue.

- Gently and carefully operate:

- The wiping action should be gentle and avoid scratching the interface surface.

- Use immediately after cleaning:

- Reconnect the interface as soon as possible after cleaning to avoid re-contamination.

Strictly following the above cleaning steps and precautions can effectively avoid re-contamination of the fiber interface and ensure communication quality.

Cleaning methods for different types of fiber couplers

The cleaning methods for different types of fiber couplers are slightly different. For single-mode and multi-mode couplers, use special fiber cleaning paper or cleaning stick to gently wipe the end face to ensure that dust and dirt are removed. For plug-in couplers, use a dust-free cloth and appropriate cleaning solvent when cleaning the outside of the connector. Fiber array couplers require more meticulousness. It is recommended to use cleaning spray and special tools to ensure the cleanliness of each end face to maintain the best signal transmission effect.

1. Cleaning methods for common interface types:

Different types of fiber coupler interfaces have slightly different cleaning methods:

- FC interface:

- You can use a sticky cleaning stick to gently wipe the interface end face.

- You can also use clean dust-free paper to gently wipe it.

- SC interface:

- Similar to FC, you can use a sticky stick or dust-free paper to wipe it.

- Pay attention to the wiping direction and wipe gently along the radial direction of the end face.

- LC interface:

- LC interface is small, and small cleaning tools such as cotton swabs can be used.

- Also be gentle and careful to avoid scratching the interface.

- MPO/MTP interface:

- This type of high-density interface requires a special cleaning card or stick.

- Gently insert the interface and rotate to clean to remove residual dirt.

Different interface types require appropriate cleaning tools and methods.

2. Cleaning in special scenarios:

In some special application scenarios, fiber coupler cleaning also requires different methods:

- High-density coupler:

- As mentioned above, the MPO/MTP interface requires a special cleaning tool.

- Clean each interface end face separately to prevent cross contamination.

- Alignment-sensitive models:

- Some couplers are very sensitive to the inclination of the end face, so be extra careful.

- When cleaning, be careful to keep the end face flat to avoid causing a decrease in coupling efficiency.

- Harsh environments:

- In environments such as outdoors and factories, dust and oil prevention measures must be taken.

- Accessories such as protective covers can be considered to reduce the risk of interface contamination.

In short, for different types of fiber couplers and application scenarios, corresponding cleaning methods and precautions need to be taken to ensure that the interface is always in the best condition.

Summary

Keeping the fiber coupler clean is the key to ensuring the performance of the fiber network. Our company is a well-known domestic supplier of optical communication products, and has long been focusing on the research and development and application of optical fiber system solutions. We provide a full range of fiber optic couplers and their cleaning tools to meet the needs of different fiber optic network scenarios.

Our products use industry-leading manufacturing processes and have achieved excellent levels in optical performance, reliability and service life. At the same time, our team of engineers will provide you with professional cleaning training and guidance services to ensure that you can correctly master the cleaning methods of fiber optic couplers. Contact us now to learn more.

Fiber Optic Coupler Cleaning FAQ

A fiber optic coupler is a device used to connect two fiber optic cables, allowing signal transmission between them.

Dirt, dust, and moisture can degrade signal quality and cause loss of data, so regular cleaning is essential.

You’ll need lint-free wipes, fiber optic cleaning solution, and possibly a fiber optic cleaning tool.

Disconnect the coupler from the network and ensure you’re working in a static-free environment.

Apply cleaning solution to a lint-free wipe and gently wipe the ferrule end-face of the coupler in a circular motion.

It’s recommended to clean couplers before each use or anytime you see visible contamination.

Yes, isopropyl alcohol wipes can be used, but ensure they are lint-free and specifically made for fiber optics.

Avoid using abrasive materials, excessive pressure, or liquids that can leave residues.

Yes, clean the coupler first, then clean the fiber ends before reconnecting.

Symptoms like increased signal loss, intermittent connectivity, or visible dirt on the coupler suggest it needs cleaning.