Low-voltage embedded cable boards are widely used in homes and commercial places. This article will focus on how to install this type of cable board. We first define the concept and main uses of low-voltage cable boards, and analyze their design purposes and advantages. Next, we will introduce the types of cable boards of different sizes and shapes, and explain the matters that should be paid attention to when selecting cable boards.

Then, we will elaborate on the installation process of embedded cable boards, provide tips and precautions during installation. Finally, we will analyze the specific methods of installing cable boards on gypsum board walls and concrete walls to provide users with reference.

The role and characteristics of low-voltage embedded cable boards

Low-voltage embedded cable boards are used in buildings and equipment to provide safe and convenient power connections. Its main features include compact design for easy installation in limited spaces; waterproof and corrosion-resistant materials to ensure long-term use; and multiple connection methods to adapt to different electrical needs. This type of cable board is often used in smart homes, industrial equipment and communication systems, improving the efficiency and safety of power management.

1. Concept and main uses of low-voltage cable board:

Low-voltage embedded cable board, also known as information panel or connection panel, is an embedded device specially used to install and manage various types of low-voltage cables.

Main application scenarios include:

- Network cabling:

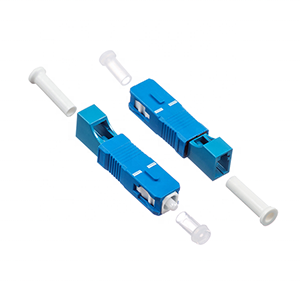

- Provide centralized access ports for network connections such as Ethernet cables and optical fibers.

- Audio/video system:

- Centralized management of HDMI, VGA, audio and other cable connections.

- Security system:

- Arrange power and signal cables for surveillance cameras, alarm equipment, etc.

Low-voltage cable boards can centrally arrange cables of various types of equipment in one place to achieve cable hiding and management.

2. Design purpose and advantages of low-voltage cable boards:

The main design purposes and advantages of low-voltage cable boards include:

- Hide cables:

- Hide a large number of low-voltage cables inside the wall or under the floor to beautify the environment.

- Centralized connection:

- Provide centralized connection ports for various types of equipment to facilitate cable management and maintenance.

- Flexible layout:

- You can choose the appropriate number and type of ports for customization according to actual needs.

- Enhanced reliability:

- Professional design and manufacturing can improve the stability and anti-interference ability of cable connections.

- Simplified construction:

- Concentrated wiring points reduce the complexity of on-site wiring and improve construction efficiency.

In short, low-voltage embedded cable boards can effectively manage and hide various types of low-voltage cables, providing reliable connection support for network, audio and video, security and other systems.

How to choose a suitable low-voltage embedded cable board

When choosing a suitable low-voltage embedded cable board, you should consider the load requirements, installation environment and connection method. Ensure that the rated voltage and current of the cable board can meet the equipment requirements, and pay attention to its waterproof, dustproof and corrosion resistance to adapt to different environments. In addition, check the size and layout of the installation space, and choose products that meet the specifications to ensure safety and stability. Brand reputation and after-sales service should also be important considerations.

1. Types of cable plates of different sizes and shapes:

Low-voltage embedded cable plates are available in a variety of sizes and shapes, mainly including:

- Single-connected cable plate:

- The most basic single interface panel, often used for single device connection.

- Dual-connected cable plate:

- Two independent interface panels combined together, suitable for multi-device connection.

- Round cable plate:

- The round design is suitable for installation in places with limited space such as desktops or walls.

- Square cable board:

- Rectangular design can integrate more connection ports and is suitable for large systems.

Cable boards of different shapes and sizes can meet the layout requirements in different scenarios.

2. Considerations for selecting cable boards:

When choosing a suitable low-voltage cable board, you need to consider the following aspects:

- Number of connections:

- Choose a cable board with the appropriate number of ports according to the number of devices that need to be connected.

- Cable type:

- Make sure the interface type provided by the cable board can match the required cable, such as HDMI, RJ45, etc.

- Installation location:

- Choose a cable board with suitable size and shape according to the actual installation scenario.

- Interface function:

- Some cable boards also integrate additional functions such as USB charging, which can be selected according to needs.

- Brand selection:

- Choose a well-known brand with good reputation to ensure product quality and after-sales service.

Taking the above factors into consideration, choosing the low-voltage cable board that best suits the actual application scenario can improve the reliability and ease of use of the overall system.

How to install a low-voltage embedded cable board

The installation steps of a low-voltage embedded cable board include: first, select a suitable location and mark the drilling point; then, use an electric drill to drill holes at the marked location and clean the dust in the hole. Then, align the cable board with the hole and fix it with screws; next, ensure the correct polarity when connecting the cable, and finally wrap the connector with insulating tape to prevent short circuit. Ensure that the installation is firm and check whether the connection is normal.

1. Low-voltage embedded cable board installation process:

The specific steps for installing a low-voltage embedded cable board on a wall or desktop are as follows:

(1) Determine the installation location:

- Select a suitable installation location based on the actual application scenario, considering the cable length and wiring method.

(2) Hole installation:

- Drill a hole of appropriate size at the selected location to ensure that the cable board can be embedded in it.

- The hole size should be measured and cut strictly according to the size specifications of the cable board.

(3) Fix the cable board:

- Put the cable board into the hole and securely install it with screws and other fixings.

- Ensure that the surface of the cable board and the wall/desktop are flat and connected after installation.

(4) Connect cables:

- Connect all required network, audio and video, power and other cables to the corresponding ports on the cable board.

- Pay attention to the neatness and reliability of cable connections.

(5) Finishing treatment:

- Clean the installation environment to ensure that the cable layout is neat and beautiful.

- You can choose to use auxiliary measures such as cable troughs to fix and hide excess cables.

2. Tips and precautions for installing low-voltage embedded cable boards:

When installing low-voltage cable boards, pay attention to the following points:

- Hole size accuracy:

- If the hole size is too large, it will affect the fixing effect of the cable board.

- Cable length planning:

- Measure the length of the cable to be connected in advance to avoid insufficient length.

- Keep the cables neat:

- Arrange and fix the connected cables to keep them neat and tidy.

- Leave space for maintenance:

- Leave a certain space around the cable board for future maintenance and repair.

- Pay attention to fire prevention requirements:

- Professional fireproof sealing measures must be taken when passing through the firewall.

Strictly abide by the above installation process and precautions to ensure the reliability and aesthetics of the low-voltage cable board installation.

How to install low-voltage embedded cable boards in special scenarios

When installing low-voltage embedded cable boards in special scenarios, environmental factors such as humidity and temperature need to be considered. In humid or dusty environments, choose cable boards with higher waterproof and dustproof grades. In addition, ensure a safe distance from other power lines to reduce interference. In limited space, plan the installation location reasonably to ensure good ventilation and heat dissipation to avoid overheating. At the same time, follow local electrical regulations to ensure safety and reliability.

1. Install low-voltage cable boards on gypsum board walls:

When installing low-voltage embedded cable boards on gypsum board walls, the following special measures need to be taken:

- Use special fixings:

- When opening holes in gypsum boards, special plastic or metal fixings should be used.

- These fixings can provide stable installation support on gypsum boards.

- Strengthen the fixed support:

- Add wooden or metal reinforcement support behind the gypsum board at the opening position.

- Ensure that the cable board will not become loose after installation due to the soft wall material.

- Pay attention to fire protection requirements:

- When opening a hole in the gypsum board wall, it is necessary to ensure that the fire resistance of the wall will not be damaged.

- Special fireproof sealing sleeves and other measures can be adopted.

These targeted installation measures can ensure that the low-voltage cable board is reliably fixed on the gypsum board wall.

2. Install low-voltage cable panels on concrete walls:

For concrete walls, the following matters need to be noted when installing low-voltage embedded cable panels:

- Choose a suitable installation method:

- Consider using fixings such as expansion bolts or chemical anchors.

- These fixings can provide stable installation support on hard concrete walls.

- Reserve installation space:

- The holes opened in the concrete wall should leave enough installation space.

- Ensure that the cable panel can be fully embedded and flush with the wall.

- Strengthen cable protection:

- When laying cables in concrete walls, metal pipes or plastic sleeves should be used for protection.

- Avoid direct contact between cables and concrete to prevent wear or damage.

By taking these targeted installation measures, it is possible to ensure that low-voltage cable panels are reliably and firmly installed on concrete walls. In short, facing different wall materials, corresponding professional skills are required when installing low-voltage embedded cable panels to ensure the stability of the installation and the satisfaction of fire protection requirements.

Summary

Reasonable installation of low-voltage embedded cable panels is the key to ensuring the performance of home and commercial network, audio/video, security and other systems. Our company has long focused on the research and development and application of cable laying products and has rich practical experience. We provide a full range of embedded cable panels and their supporting installation tools to meet the needs of different scenarios.

Our products use industry-leading technical solutions and achieve excellence in performance, aesthetics and reliability. At the same time, our team of engineers will provide you with professional on-site guidance and training services to ensure that the installed cable board solutions can meet your actual needs to the greatest extent. Contact us now to learn more.

Low Voltage Embedded Cable Board FAQ

It’s a wall plate designed to conceal and manage low voltage cables for a clean look.

You’ll need a drill, screwdriver, drywall saw, and a level.

Choose a location that aligns with your audio/video equipment for optimal cable management.

Yes, always turn off power to nearby electrical outlets for safety.

Use a drywall saw to cut a hole according to the plate’s template or dimensions.

Low voltage cables like HDMI, coaxial, or speaker wires are suitable.

Secure the plate with screws through the provided mounting holes into the wall.

Yes, it’s suitable for drywall, but ensure the wall structure can support it.

While not mandatory, a bracket can provide additional support and stability.

Yes, you can paint it to match your wall color for a seamless look.