MPO fiber connectors are widely used in data centers and high-speed networks. This article will focus on the common faults of MPO fiber patch cords and their countermeasures. We will first define the characteristics and components of MPO fiber connectors and explain the role of MPO fiber patch cords in optical transmission. Next, we will analyze the common faults that MPO fiber patch cords may encounter, including end face contamination, poor connection, fiber breakage, excessive bending, and environmental factors.

We will explain the causes of various types of faults and their impact on signal transmission, and provide corresponding prevention and repair measures. Subsequently, we will introduce the specific steps for MPO fiber patch cord fault diagnosis and repair. Finally, we will share the best practices for preventing MPO fiber patch cord failures, including usage and management recommendations, and tips for extending their service life.

The structure and working principle of MPO fiber jumper

Let me introduce you to the structure and working principle of MPO fiber jumper in detail:

The characteristics and composition of MPO fiber connector:

MPO (Multi-fiber Push On) fiber connector is a multi-core fiber interface standard, the main features are as follows:

- It adopts a flat rectangular shell design with a size of approximately 22.5×7.0 mm

- It integrates 8, 12 or 24 optical fiber cores to achieve multi-channel parallel transmission

- It adopts a push/pull locking mechanism to quickly connect and disconnect the optical fiber

- Provide two interface types, PC (Physical Contact) and APC (Angled Physical Contact)

The main components of the MPO connector include:

- Fiber core – Responsible for the actual transmission of optical signals

- Positioning guide pin – used to accurately locate and align the optical fiber core

- Housing – provides mechanical protection and locking function

- End face – input/output interface of optical signals

Working principle of MPO fiber jumper:

MPO fiber jumper consists of the following main parts:

- Multi-core optical fiber – realize multi-channel parallel optical transmission

- MPO connectors at both ends – used for quick docking with device ports

- Sheath layer – Provide mechanical protection such as tensile and bending resistance

In the process of optical transmission, MPO fiber jumpers play the following roles:

- Multi-core optical fibers can transmit multiple optical signals at the same time

- MPO connectors ensure accurate docking with device ports

- The sheath layer enhances the damage resistance of the jumper

- The overall design improves the stability and reliability of the connection

In short, MPO fiber jumpers are widely used in data centers, optical switches and other scenarios due to their high density and fast connection characteristics. They are an important medium for achieving high-speed parallel optical transmission.

Common faults of MPO fiber jumpers

Let me introduce you to several common faults of MPO fiber jumpers and their solutions in detail:

End face contamination:

- MPO end faces may be contaminated by dust, oil stains and other pollutants

- This will cause reflection and scattering of optical signals, causing transmission loss

- It can be effectively cleaned with special fiber cleaners and cleaning cards

Poor connection:

- Wrong connection operation will lead to incomplete MPO connector docking

- This will cause poor alignment between the fiber core and the port, resulting in poor contact

- Strictly follow the correct MPO connection steps, such as cleaning, alignment, and locking

Fiber breakage:

- MPO fiber may be partially broken due to external force

- Broken optical fiber will cause complete signal interruption and transmission failure

- Avoid mechanical damage such as excessive pulling and bending of the jumper

Excessive bending:

- If the bending radius of the MPO jumper is too small, it will cause macro bending loss

- This will greatly reduce the power of the optical signal and affect the transmission distance and reliability

- Ensure that the bending radius of the MPO jumper is not less than the minimum bending radius of the optical fiber</ li>

Environmental factors:

- Environmental changes such as temperature and humidity will cause thermal expansion and contraction of MPO components

- Thereby causing optical coupling mismatch and transmission performance degradation

- MPO patch cords that are resistant to high and low temperatures and humidity should be selected, and isolation should be done

In short, end face contamination, poor connection, fiber breakage, excessive bending, and harsh environment may cause various faults in MPO fiber patch cords. By taking correct preventive and maintenance measures, these problems can be effectively avoided and the reliability of the MPO optical transmission system can be ensured.

MPO fiber jumper fault diagnosis and repair

Let me introduce you to the common methods of diagnosing and repairing MPO fiber jumper faults:

How to diagnose faults?

(1) Visual inspection

- Carefully check the appearance of the MPO connector and fiber jumper to see if there is obvious contamination or damage

(2) Insertion loss test

- Use tools such as optical power meters to measure the optical power and insertion loss of MPO jumpers

- Abnormal insertion loss may indicate poor connector connection or end face contamination

(3) Reflection loss test

- Use OTDR (Optical Time Domain Reflectometer) to detect the reflection loss of MPO patch cord

- Large reflection peaks indicate that there may be problems such as loose connectors or fiber breakage

(4) Fiber length test

- Use OTDR to measure the actual length of the fiber in the MPO patch cord

- Compare with the designed length to determine whether there is bending or breakage

What are the maintenance steps?

(1) End face cleaning

- Use a special fiber cleaning fluid and cleaning card to carefully clean the end face of the MPO connector

(2) Connection repair

- Re-install the MPO connector correctly

- Ensure that the connector is firmly fixed and the fiber cores are well aligned

(3) Break repair

- For slightly damaged MPO fibers, they can be repaired by hot-melt joints

- For severely broken ones, all fiber cores need to be cut and reconnected

(4) Bend correction

- Adjust the wiring of the MPO jumper to ensure that the bending radius meets the requirements

- If necessary, auxiliary measures such as sheath tubes can be used to support the fiber

(5) Environmental adaptation

- In an environment with drastic changes in temperature and humidity, sufficient adaptation time should be given

- Avoid performance degradation of MPO patch cords under environmental impact

In short, diagnosis and repair of MPO fiber patch cord failures require systematic detection methods and appropriate repair measures based on the type of failure. Only in this way can the reliability and stability of the MPO optical transmission system be ensured.

Best Practices for Preventing MPO Fiber Patch Cord Failures

Let me summarize the best practices for preventing MPO fiber patch cord failures:

Usage and management suggestions for MPO fiber patch cords:

(1) Endface cleaning

- Regularly use a dedicated fiber cleaning tool to clean the endface of the MPO connector

- Avoid direct contact of the connector with dust, oil stains and other contaminants

(2) Correct connection

- Strictly follow the correct connection steps for the MPO connector

- Ensure that the connector is well connected and that all fiber cores are aligned

(3) Reasonable wiring

- Plan the wiring path of the MPO patch cord to avoid excessive bending

- Leave an appropriate length margin for installation and maintenance

(4) Mechanical protection

- Use pipes, sheaths, etc. to protect the MPO patch cord from external damage

- Specially strengthen protection for areas that may be hit

(5) Environmental control

- Choose MPO fiber patch cords that are suitable for the use environment

- Try to avoid drastic temperature and humidity changes

Tips for extending the service life of MPO fiber patch cords:

(1) Regular inspections

- Periodically conduct a comprehensive appearance and performance inspection of the MPO patch cord

- Discover and repair possible problems in a timely manner

(2) Proper storage

- Store spare MPO patch cords properly to avoid contamination or mechanical damage

- The temperature and humidity of the storage environment should be controlled within a reasonable range

(3) Spare replacement

- Prepare an appropriate amount of spare MPO fiber patch cords according to actual usage

- So as to replace damaged or degraded patch cords in a timely manner

(4) Professional maintenance

- Take professional maintenance and care measures for key MPO fiber jumpers

- Such as regular calibration, professional cleaning, etc., to ensure long-term stable operation

In short, by doing a good job in the daily use management of MPO fiber jumpers, regular inspection and maintenance, and taking appropriate protection measures, you can effectively prevent the occurrence of various faults, extend the service life of the jumpers, and ensure the reliability of the MPO optical transmission system.

Summary

Proper use and maintenance of MPO fiber jumpers are essential for building a reliable high-speed optical network. Our company has long been focusing on the research and development and production of optical communication equipment and its supporting products, and has rich industry experience. The MPO fiber jumper products we provide have reached the industry-leading level in terms of end face quality, connection performance, and pressure resistance, and can meet your needs for stable and efficient optical transmission.

Whether you use MPO fiber jumpers in data centers, telecommunications networks, or industrial automation, we can provide you with professional diagnosis and maintenance services. At the same time, our technical team will provide you with comprehensive training and guidance to help you master the best use and management practices of MPO fiber jumpers. Contact us now to learn more.

MPO Fiber Patch Cords FAQ

MPO fiber optic patch cords are pre-terminated, ready-to-use fiber optic cables that feature an MPO connector on one or both ends, allowing for the connection of multiple fibers in a single, compact connector.

MPO fiber optic patch cords are typically available in 12-fiber and 24-fiber configurations, although other fiber counts like 8-fiber and 16-fiber may also be used in some applications.

MPO fiber optic patch cords are widely used in high-density fiber optic applications, such as data centers, telecommunications networks, and storage area networks, where they provide efficient and space-saving connectivity.

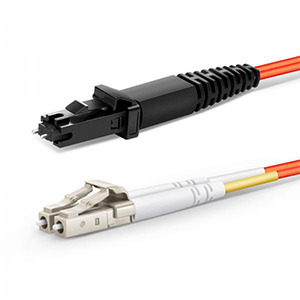

The key difference is the use of the MPO multi-fiber connector instead of individual fiber connectors, such as LC or SC, allowing for the simultaneous connection of multiple fibers in a single step.

The main advantages include higher fiber density, simplified cable management, faster installation, and reduced deployment time compared to individual fiber patch cables.

MPO patch cords can feature various connector types, such as MPO-12 or MPO-24, as well as different polarity configurations (type A, type B, or type C) to ensure proper signal transmit and receive alignment.

Proper installation of MPO patch cords involves careful handling, correct mating of the MPO connectors, and the use of specialized cleaning and inspection tools to maintain the connector endface quality.

Key performance metrics include insertion loss, return loss, and optical bandwidth, which should be verified through comprehensive testing and certification before deployment.

Maintenance tasks may include regular cleaning, visual inspection, and the use of diagnostic tools to identify and address any issues with the MPO connectors or the fiber optic links.

Ongoing advancements include the introduction of higher-density MPO configurations, the integration of MPO connectivity with new network architectures, and the optimization of patch cord designs for improved performance and ease of use.