In this article, I will take you to delve into the definition, structure, function and application scenarios of fiber optic pigtails. As a short fiber optic cable, fiber pigtail plays an important role in fiber optic communications, providing an efficient and reliable solution for your network connection.

As an important component of optical fiber communication systems, optical fiber pigtails play a key role in the field of modern communications. It is an optical fiber cable used to connect optical fiber transceivers and optical fiber transmission equipment. This article will delve into the definition, structure, function and application scenarios of fiber optic pigtails.

Definition and structure of fiber optic pigtail

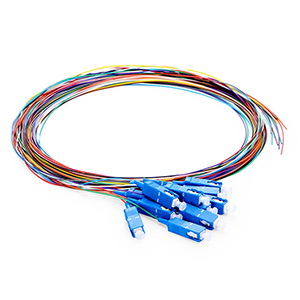

Fiber pigtail is a short fiber optic cable used to connect fiber optic connectors to fiber optic equipment. It is usually used to connect fiber optic transceivers, fiber optic converters, fiber optic switches and other equipment in fiber optic communication systems to achieve the transmission and reception of optical signals.

The structure of an optical fiber pigtail usually includes the following main components:

-

Fiber Core: The fiber core of the fiber pigtail is the most critical part. It is a very thin wire of glass or plastic used to transmit light signals. The diameter of the fiber core can be single-mode or multi-mode type, depending on the required transmission distance and the characteristics of the optical signal.

-

Buffer: The strand is the protective layer of the optical fiber core, usually surrounded by a layer of plastic material. Its main function is to protect the optical fiber core from physical damage and environmental interference. Stranded wire can also provide flexibility and bend radii to accommodate different installation and cabling needs.

-

Jacket: The protective jacket is the outer layer of the optical fiber pigtail and is used to protect the entire connection line from external physical damage and environmental factors. It is usually made of wear-resistant, corrosion-resistant and flame-retardant materials, such as polyvinyl chloride (PVC) or low-smoke halogen-free (LSZH) materials.

-

Connector Types: One end of the fiber optic pigtail is usually equipped with a fiber optic connector for connecting to fiber optic equipment. Common fiber optic connector types include SC (Subscribe Connector), LC (Lucent Connector), ST (Straight Tip Connector) and FC (Ferrule Connector), etc. Different connector types are suitable for different device interface and transmission needs.

The structure and components of fiber optic pigtails can be customized according to specific application needs and standards. When selecting and installing fiber optic pigtails, factors such as fiber core type, connector compatibility, and protective sleeve performance need to be considered to ensure stable and reliable optical signal transmission.

Functions and advantages of optical fiber pigtails

Fiber pigtails have many functions and advantages in fiber optic communications, the following are some of them:

Function:

-

Signal transmission: The main function of optical fiber pigtails is to realize high-speed and long-distance transmission of optical signals. Since optical fiber pigtails use optical fibers as transmission media, optical signals can be transmitted through the fiber core in the form of light, thereby achieving low-loss and high-bandwidth data transmission.

-

Connector protection: Fiber optic pigtails play a role in connecting the fiber optic connector and the fiber optic equipment, and also play a role in protecting the connector. The fiber optic pigtail’s strands and protective sleeve protect the connector from physical damage, bending, or strain, ensuring a stable and reliable connection.

-

Fiber optic connection extension: Fiber optic pigtails can be used to extend the length of fiber optic connections. When the distance between optical fiber devices exceeds the range that can be covered by direct use of optical fiber connectors, optical fiber pigtails can be used to extend the connection to achieve long-distance optical signal transmission.

Advantages:

-

Convenient installation: Fiber pigtails have a more convenient installation process than directly connecting fiber optic connectors. Optical fiber pigtails are usually pre-configured with connectors, and users only need to plug them into the corresponding device interface to establish a connection, eliminating the manual installation and adjustment steps of optical fiber connectors and improving installation efficiency.

-

Flexibility: Fiber optic pigtails have high flexibility and adjustability. Because the strands and protective sleeves of fiber optic pigtails have a certain degree of flexibility, they can be bent, folded, and routed according to actual needs. This allows fiber pigtails to be flexibly used in different wiring environments and space constraints to meet various complex connection requirements.

In summary, fiber optic pigtails have important functions and multiple advantages in fiber optic communications. They not only enable high-speed, long-distance optical signal transmission, but also protect connectors and extend the length of fiber optic connections. Compared with fiber optic connectors, fiber optic pigtails have a convenient installation process and flexible wiring characteristics, making them an indispensable component of fiber optic communication systems.

Application scenarios of optical fiber pigtails

Fiber pigtails have a wide range of practical applications in different application scenarios. Here are some examples:

-

Fiber Distributed Sensing: Fiber pigtails play an important role in the field of fiber distributed sensing. By combining optical fiber pigtails with optical fiber sensing systems, real-time monitoring and measurement of physical parameters such as temperature, pressure, strain, etc. can be achieved. This application is widely used in oil well monitoring, seismic monitoring, pipeline safety monitoring and other fields.

-

Fiber Optic Sensing Network: Fiber pigtails also play an important role in fiber optic sensing networks. By connecting fiber optic sensors and data collection nodes, fiber optic pigtails can transmit the signals acquired by the sensors to the data center or monitoring system to achieve real-time monitoring and analysis of the environment, structure or safety status. This application is widely used in fields such as intelligent transportation systems, smart buildings, and industrial monitoring.

-

Fiber Optic Testing Equipment: Optical fiber pigtails are used in optical fiber testing equipment to connect the test instrument and the equipment under test. For example, during the installation and maintenance of optical fiber networks, optical fiber pigtails are used to connect optical power meters, spectrometers, OTDR (optical time domain reflectometer) and other test equipment with optical fiber transmission equipment for signal quality testing, fault location and performance evaluation. Waiting for work.

Fiber optic pigtails are important in areas such as data centers, telecommunications networks and wide area networks:

-

Data center: In large data centers, optical fiber pigtails are widely used to connect key equipment such as servers, network switches, and storage devices to achieve high-speed and reliable data transmission. The low loss and high bandwidth characteristics of fiber optic pigtails make them ideal for meeting the needs of large-scale data centers.

-

Telecommunications network: In modern telecommunications networks, fiber optic pigtails are used to connect fiber optic switches, optical terminals, OLT (optical transmission terminals) and other equipment to support high-speed broadband communication and transmission services. Optical fiber pigtails can provide reliable signal transmission and high-speed data transmission capabilities, meeting the bandwidth and reliability requirements of telecommunications networks.

-

Wide Area Network: In a wide area network (WAN), fiber optic pigtails are widely used to connect network nodes in different geographical locations to achieve high-speed, long-distance data transmission. The low loss and anti-interference capabilities of fiber optic pigtails make them the preferred solution for supporting large-scale data transmission and long-distance communications.

To summarize, fiber pigtails play an important role in applications such as fiber optic distributed sensing, fiber optic sensing networks, and fiber optic testing equipment. In addition, in fields such as data centers, telecommunications networks, and wide area networks, optical fiber pigtails are also of irreplaceable importance and are used to achieve high-speed, reliable data transmission and communication services.

Types and specifications of fiber optic pigtails

There are two main types of fiber optic pigtails: single-mode fiber optic pigtails and multi-mode fiber optic pigtails.

-

Single-mode Fiber Patch Cord: Single-mode fiber patch cord is an optical fiber cable used to transmit a single optical mode. Its core diameter is smaller (usually 9/125 microns), enabling longer distance transmission and lower transmission loss. Single-mode fiber optic pigtails are suitable for applications requiring high bandwidth and long-distance transmission, such as long-distance communications, fiber optic sensing, and data center interconnects.

-

Multimode Fiber Patch Cord: Multimode fiber patch cord is an optical fiber cable used to transmit multiple light modes. Its core diameter is larger (usually 50/125 or 62.5/125 microns), which can accommodate multiple light modes and support short-distance transmission. Multimode fiber optic pigtails are suitable for short-distance communications and local area network applications such as office networks, data center internal connections, and video transmission.

In addition to type, fiber optic pigtails also need to comply with a series of relevant specifications and standards to ensure their performance and interoperability. The following are two common fiber pigtail related specifications:

-

TIA-568-C.3: A standard formulated by the Telecommunications Industry Association, which stipulates the connector type, core diameter, interface standards and test requirements of optical fiber pigtails. This standard is mainly applicable to optical fiber systems for data communications and local area networks.

-

IEC 61754-4: A standard issued by the International Electrotechnical Commission that specifies the interface dimensions, optical performance and coordinated test requirements for fiber optic connectors and accessories. IEC 61754-4 covers various types of fiber optic connectors, including fiber optic pigtail connectors.

These specifications and standards ensure the interoperability of fiber optic pigtails, allowing fiber optic pigtails produced by different manufacturers to be compatible and interactively used in fiber optic communication systems. At the same time, they also provide guidance on the quality and performance of optical fiber pigtails to ensure the reliability and transmission quality of optical fiber connections.

Installation and maintenance of fiber optic pigtails

Proper installation and maintenance of fiber optic pigtails is critical to ensuring the performance and reliability of fiber optic connections. Here are some recommendations and best practices for fiber optic pigtail installation and maintenance:

Install fiber optic pigtails:

-

Clean the work area: Before installing the fiber optic pigtail, make sure the work area is clean to avoid dust and debris from entering the connector end face.

-

Connector cleaning: Before connecting the fiber pigtail, be sure to clean the connector end face. Using appropriate fiber optic cleaning tools and cleaners, gently wipe the connector end faces to remove dirt and contaminants.

-

Ensure proper alignment: When inserting the fiber optic pigtail into the connector, ensure that the core of the fiber is properly aligned with the center hole of the connector. Avoid damaging the fiber core or causing additional insertion loss.

-

Connector protection: After installing the optical fiber pigtail, use a connector sleeve to protect the connector end face to prevent contamination and physical damage. Keep connectors clean and intact to ensure good optical performance.

Maintain fiber pigtails:

-

Periodic inspections: Regularly inspect fiber connections to ensure their stability and performance. Check the connector end face for contamination, scratches or damage, and clean or replace it in time.

-

Clean connector end faces: Clean connector end faces regularly to remove contaminants. Use fiber optic cleaning tools and cleaners to wipe gently and follow the instructions for use of the cleaning tools and cleaners.

-

Prevent Tension and Bends: Avoid applying excessive tension or bends to fiber pigtails to avoid damaging the fiber or connector. Make sure the bend radius of the fiber optic pigtail meets the manufacturer’s recommendations.

-

Protect fiber optic connections: Use appropriate protective measures, such as jackets, protective sleeves, etc., to protect fiber optic connections from physical damage and environmental effects.

-

Recording and identification: Record the installation location and related information of the optical fiber pigtail, and label it appropriately for future maintenance and troubleshooting.

Please note that for more complex fiber optic network systems and advanced maintenance, professional fiber optic technicians may be required. When performing any installation or maintenance work, please refer to the manufacturer’s guidelines and recommendations and follow applicable safety regulations.

Summary:

Thank you for reading our blog! We deeply explore the definition, structure, functions and application scenarios of fiber optic pigtails. As a short fiber optic cable, fiber pigtail plays a key role in fiber optic communications, providing an efficient and reliable solution for your network connection.

Fiber pigtail is a short fiber optic cable that connects fiber optic connectors to fiber optic equipment. It consists of optical fiber core, twisted wire, protective sleeve and connector, ensuring the fast transmission of optical signals and the reliability of the connection.

fiber optic pigtails FAQ

fiber pigtail is used in fiber optic communications to provide a temporary or permanent connection between fiber optic cables and devices. It typically consists of a short length of fiber optic cable with a connector on one end and exposed fibers on the other, ready for splicing or termination.

A pigtail cable is essentially the same as a fiber pigtail. It is used to connect fiber optic cables to devices or components such as transceivers, switches, or patch panels. The pigtail cable provides a convenient and standardized way to interface between different fiber optic components.

A fiber pigtail refers to the short length of fiber optic cable with exposed fibers, while a connector is a specific type of termination on the end of a fiber optic cable. The fiber pigtail is often used for splicing or connecting to devices, whereas the connector is used for direct connections between fiber optic cables or devices.

Fiber pigtailed components are optical devices or components that come with a pigtail attached. These components can include lasers, photodiodes, couplers, isolators, switches, and other active or passive devices. The pigtail allows for easy integration and connection to the fiber optic system.

A fiber optic pigtail is a short length of fiber optic cable with one end terminated with a connector and the other end with exposed fibers. To splice a fiber optic pigtail, you would typically strip the protective coating from the pigtail’s exposed fibers, carefully align them with the fibers of another cable or component, and then fuse them together using a fusion splicer or mechanically splice them using a splice connector.

There are different types of fiber pigtails, including single-mode and multimode. Single-mode pigtails are designed for long-distance transmission with a narrow core that allows for a single pathway of light. Multimode pigtails are used for shorter distances and have a larger core that enables multiple pathways of light. Both types can come with various connector types, such as SC, LC, ST, or FC, depending on the application and equipment requirements.

Fiber pigtail related products

-

Fiber Optic Pigtail Customization

-

LC APC 12 core uncased fiber optic pigtail

-

LC APC 12-core tubed optical fiber pigtail

-

LC UPC 12 core uncased fiber optic pigtail

-

LC UPC 12-core tubed optical fiber pigtail

-

SC APC 12 core uncased fiber optic pigtail

-

SC APC 12-core tubed optical fiber pigtail

-

SC UPC 12 core uncased fiber optic pigtail

-

SC UPC 12-core tubed optical fiber pigtail