Fiber splitters play an important role in optical communications. This article will focus on PLC (planar light guide) fiber splitters. We will first explain the basic working principle of fiber splitters and explain their applications in optical networks. Next, we will define the basic structure of PLC fiber splitters and explain their manufacturing process and main features.

Then, we will focus on the key performance indicators of PLC fiber splitters, including splitting ratio, insertion loss, isolation, fiber interface type, and operating temperature range. We will analyze the impact of these indicators on the application of PLC splitters. Finally, we will introduce the typical deployment scenarios of PLC fiber splitters in different optical networks and analyze their advantages in various application scenarios.

Overview of Fiber Splitter

Fiber splitters are a key component in optical fiber communication systems that are used to distribute optical signals from one optical fiber channel to multiple optical fiber channels. The following is an overview of the basic working principle and application of fiber optic splitters:

Basic working principle of fiber optic splitters:

An optical splitter is an optical network device used to distribute a single optical fiber signal to multiple output ports. Its basic working principle is as follows:

- The optical splitter receives optical signals from a single input optical fiber.

- The input optical signal is divided into multiple output signals through optical diffraction or interference.

- Each output port can receive a portion of the power of the input optical signal.

- The number of output ports is usually 2, 4, 8, 16, 32, etc., which can be selected according to needs.

In this way, the signal of a single input optical fiber can be distributed to multiple output ports for use by multiple users or devices. Fiber optic splitters are usually integrated into optical network equipment to play their key splitting function.

Application of fiber splitters in optical networks:

Fiber splitters are widely used in optical networks, mainly including the following scenarios:

(1) Passive optical network (PON):

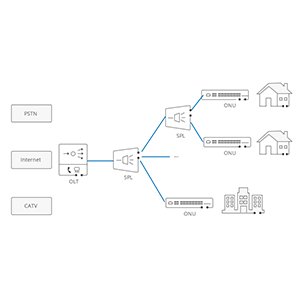

- Fiber splitters are widely used in optical distribution networks of passive optical networks (GPON, EPON, etc.).

- Distribute fiber signals from one port to multiple user terminals to achieve fiber to the home (FTTH).

(2) Optical access network:

- Fiber splitters are used to distribute trunk fiber signals to access network users in different areas.

- Support individual access and management of users.

(3) Optical trunk network:

- Fiber optic splitters can be used for optical signal distribution and branching in trunk networks.

- Realize power distribution and signal distribution of trunk optical fibers.

(4) Optical distribution frame:

- Fiber optic splitters are integrated in optical distribution frames to distribute and manage optical fiber signals.

- Convenient for configuration and rearrangement of optical fiber connections.

In short, fiber optic splitters play an indispensable role in various optical networks due to their ability to distribute single optical fiber signals to multiple outputs. It is one of the key devices for optical signal distribution and management in optical networks.

Definition of PLC fiber splitter

PLC fiber splitter is an integrated optical device that realizes the distribution of optical signals through optical waveguide technology. It can distribute an optical signal to multiple output ports in a certain proportion to realize the multi-way distribution of optical signals.

Basic structure of PLC fiber splitter:

PLC (Planar Lightwave Circuit) is an integrated optical device that realizes the distribution of optical signals through optical waveguide technology. It can distribute an optical signal to multiple output ports in a certain proportion to realize the multi-way distribution of optical signals

- Input fiber: introduces optical signals into PLC chip.

- PLC chip: integrates quartz-based optical waveguide network to realize the splitting of optical signals.

- Output fiber: the split optical signal is output from multiple output ports.

PLC chips use precision-controlled optical waveguide technology to split the input optical signal and transmit it to multiple output ports. This integrated structure makes the PLC splitter have the advantages of small size and stable performance.

PLC splitter manufacturing process:

PLC splitter manufacturing mainly uses the following processes:

(1) Quartz-based PLC technology:

- PLC chips usually use high-purity quartz glass as the substrate material.

- The doping layer is deposited on the quartz substrate to form the required waveguide structure.

(2) Optical waveguide splitting principle:

- PLC splitters use the splitting characteristics of optical waveguides to split the input optical signal into multiple outputs.

- Through coupling and interference between optical waveguides, a stable and reliable splitting function is achieved.

This manufacturing process based on planar optical waveguide technology gives the PLC splitter advantages such as small size and high manufacturing precision.

Main features of PLC splitter:

(1) Multi-way splitting can be achieved:

- PLC splitter can provide 2, 4, 8, 16, 32 and other splitting paths.

- Meet the requirements of different application scenarios for the number of splitting ports.

(2) Low insertion loss:

- The typical insertion loss of PLC splitter is between 3-6dB, which is relatively low.

- It is conducive to ensuring the transmission performance and power budget of the optical network.

(3) High reliability and stability:

- Based on quartz-based PLC technology, PLC splitters have high reliability and stability.

- Able to withstand long-term operation under harsh environmental conditions.

In short, PLC fiber splitters are widely used in various optical network systems due to their integrated design, low loss characteristics and excellent reliability. They are one of the important passive optical devices in optical networks.

Main performance indicators of PLC fiber splitters

The main performance indicators of PLC fiber splitters include insertion loss, return loss, uniformity and wavelength range. Insertion loss reflects signal transmission loss, return loss refers to signal reflection loss, uniformity describes the uniformity of signal distribution, and wavelength range indicates the applicable spectral range of the device.

- Split ratio:

- The split ratio of a PLC splitter refers to the ratio of the input optical power to each output port.

- Typical split ratios are 1:2, 1:4, 1:8, 1:16, 1:32, etc.

- The more balanced the split ratio, the closer the optical power of each output port, which is conducive to application flexibility.

- Insertion loss:

- The single-fiber insertion loss of a PLC splitter refers to the total loss from the input end to any output end.

- The single-channel insertion loss refers to the loss of any output port.

- The lower the insertion loss, the better the transmission performance and power budget of the optical network.

- Isolation:

- The isolation of a PLC splitter refers to the degree of mutual isolation between the output ports.

- High isolation can prevent the optical signals from coupling and interfering with each other between the output ports.

- Good isolation is conducive to ensuring the quality of the optical signal.

- Fiber optic interface type:

- Common fiber optic interfaces of PLC splitters include standard types such as SC, LC, and FC.

- Different interface types are suitable for different application scenarios and need to be selected according to actual needs.

- Operating temperature range:

- The operating temperature range of a PLC splitter is generally -5~+70℃.

- Wide temperature adaptability is conducive to reliable operation in harsh environments.

- Temperature is a key factor affecting the performance and life of PLC splitters.

In summary, the main performance indicators of PLC fiber splitters include splitting ratio, insertion loss, isolation, fiber interface type and operating temperature range. These indicators directly determine the applicability and performance of PLC splitters in different optical network applications. Network planners need to choose appropriate PLC splitter products according to specific needs.

Typical application scenarios of PLC fiber splitters

PLC fiber splitters are widely used in fiber-optic communication networks, such as FTTH (fiber to the home), data centers and fiber-optic sensor systems. They can effectively distribute optical signals, improve system flexibility and reliability, and support multi-user access and network expansion.

Passive Optical Network (PON):

- PLC splitter is a key component in passive optical networks such as GPON and EPON.

- Distribute the single optical fiber signal from the optical line terminal (OLT) to multiple user terminal devices (ONT).

- Use the low loss and high reliability characteristics of PLC splitter to effectively support the coverage and access of PON network.

Optical Access Network:

- PLC splitter is used for optical signal distribution in optical access network.

- Distribute the trunk optical fiber signal to user access points in different areas.

- Flexible number of splitting ports meets the needs of access networks of different scales.

Optical trunk network:

- PLC splitters are used for branching and distributing optical signals in trunk networks.

- Distribute optical signals on the trunk to different transmission paths or devices.

- High reliability helps ensure stable transmission of the trunk network.

Optical distribution frame:

- PLC splitters are integrated in optical distribution frames to manage and distribute optical fiber connections.

- Provide multi-channel optical distribution to facilitate the configuration and rearrangement of optical fiber connections in the distribution frame.

- High-density multi-channel optical splitting function meets the centralized management needs of the distribution frame.

The advantages of PLC fiber splitters in the above application scenarios are mainly reflected in:

- Low loss: The lower insertion loss of PLC splitters is conducive to improving the transmission performance of optical networks.

- High reliability: Based on quartz-based PLC technology, it has excellent environmental adaptability and long-term stability.

- Flexible splitting: A variety of splitting port numbers meet the needs of networks of different scales and are easy to deploy.

- Integration: PLC chips have high integration, which is conducive to the miniaturization and modularization of optical network equipment.

Therefore, PLC fiber splitters have become an indispensable and important component in various optical networks, playing a key role in improving network performance and reliability.

Summary

PLC fiber splitters are key components for building high-performance optical networks. Our company has long been focusing on the research and development and application of PLC splitters and has rich practical experience. We provide various high-performance PLC splitter products, which are widely used in FTTx, 5G fronthaul, data centers and other fields.

Our PLC splitters adopt the industry-leading manufacturing process and have achieved excellent levels in key performance indicators such as splitting ratio, insertion loss, and isolation. At the same time, our team of engineers will provide you with professional demand analysis and solution design services to ensure that the selected PLC splitter can meet your actual needs to the greatest extent. Contact us now to learn more. We will do our best to provide you with the best products and solutions.

PLC fiber splitter FAQ

A PLC (Planar Lightwave Circuit) fiber splitter is an optical device used in fiber optic networks to split a single optical signal into multiple outputs. It enables the distribution of light signals to multiple fibers with minimal loss and high uniformity.

A PLC fiber splitter uses a planar lightwave circuit to split the input signal into several output channels. The device relies on the principles of waveguide technology to achieve precise and consistent splitting ratios.

PLC fiber splitters are commonly used in telecommunications networks, data centers, and broadband networks to distribute optical signals to multiple endpoints or branches.

PLC fiber splitters are available in various split ratios, such as 1×2, 1×4, 1×8, 1×16, 1×32, and 1×64, depending on the number of output fibers required.

PLC fiber splitters offer high performance, low insertion loss, wide wavelength range, and excellent uniformity. They are also highly reliable and have a compact form factor compared to other types of splitters.

Yes, PLC fiber splitters are available for both single-mode and multi-mode fiber applications. It’s important to choose the correct type based on the fiber type used in the network.

The typical insertion loss for a PLC fiber splitter is generally low, usually around 3.5 dB to 4.5 dB, depending on the splitter ratio and the specific design of the splitter.

PLC fiber splitters are designed to be stable across a wide range of temperatures, but extreme temperature fluctuations can potentially affect performance. They are typically tested and rated for specific temperature ranges.

Choose a PLC fiber splitter based on factors such as the required split ratio, the type of fiber (single-mode or multi-mode), operating wavelength, and environmental conditions. Ensure that the splitter meets the specifications needed for your network design.

PLC fiber splitters generally require minimal maintenance. Regular inspection for physical damage, proper handling, and ensuring that connectors are clean and properly aligned can help maintain optimal performance.