Hello everyone! I believe you must have some understanding of the important position of LC fiber optic distribution frame in the fiber optic network. As a highly integrated and easy-to-manage optical fiber cabling solution, LC patch panels are widely favored in data centers, carrier networks and other fields. Today I am very happy to provide you with an in-depth analysis of the technical characteristics, main types and correct installation management methods of LC patch panels. By fully grasping the advantages of LC patch panels, I believe you will be able to choose the best solution for your optical fiber network and further improve the overall wiring efficiency and network manageability.

Overview of LC fiber optic distribution frame

Let me give you an overview of LC optical fiber distribution frame:

Definition and development history of LC optical fiber distribution frame:

- LC is the abbreviation of “Lucent Connector”, which is a miniaturized optical fiber connector.

- LC patch panel is an optical fiber distribution management system using LC connectors.

- LC connector was developed by Lucent in 1995 and has gradually become the mainstream interface for optical fiber networks.

The role of LC patch panel in optical fiber network cabling:

- Provides a modular optical fiber connection and management platform, which is conducive to flexible deployment of the network.

- Ensure the stability and reliability of optical signal transmission through orderly optical fiber cabling.

- It helps in network maintenance and troubleshooting, and improves the manageability of optical fiber networks.

The main advantages of LC patch panels compared to other types:

- Small size, takes up less space, and is suitable for high-density fiber optic cabling applications.

- The optical signal transmission performance is excellent, and the optical loss is lower than traditional SC and FC connectors.

- The connection operation is simple and convenient, which is convenient for installation and maintenance by non-professionals.

- The interface cost is relatively low and it is a cost-effective optical fiber wiring solution.

- It has good matching with fiber optic jumpers and can form a complete fiber optic cabling system.

In general, LC optical fiber distribution frame has become a mainstream optical fiber distribution solution widely used in today’s optical fiber networks due to its small and compact design, excellent optical performance and good economy. It plays an important role in ensuring the quality and maintainability of fiber optic network cabling.

Technical characteristics of LC optical fiber distribution frame

Let me introduce to you the technical characteristics of LC optical fiber distribution frame in detail:

Physical structure and functional characteristics of LC patch panel:

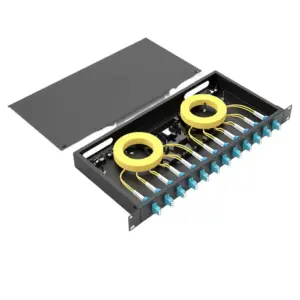

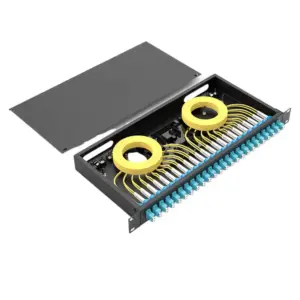

- Shell structure: Made of metal or high-strength plastic to provide good mechanical strength.

- Connection interface: Use standard LC type optical fiber connector to realize optical signal input and output.

- Management wiring: It has a drawer-type pull-out design to facilitate the introduction and management of optical fibers.

- Modular design: patch panel modules of different sizes can be used according to needs.

- Equipped with optical power monitoring: Optional optical power detection unit can monitor the transmission status.

LC patch panel performance in terms of optics, mechanics, integration, etc.:

Optical performance: Using high-precision LC connector, the optical signal transmission loss is less than 0.3dB. The optical fiber alignment mechanism is sophisticated to ensure stable and reliable optical coupling. Optional optical power monitoring is available to facilitate monitoring of optical signal transmission status.

Mechanical properties: The structural design is sturdy and durable, and can withstand large mechanical shock and vibration. The connector has a long plugging and unplugging life, usually more than 500 times. It has good dust-proof and moisture-proof performance and is suitable for harsh environment applications.

Integration features: Using modular design, the wiring capacity can be flexibly expanded according to needs. Compact size facilitates high-density fiber cabling management. Equipped with a drawer-type pull-out design for convenient maintenance and fiber optic connection operations.

Key technical indicators and their significance of LC patch panel:

- Optical signal transmission loss: reflects the optical coupling efficiency and determines the signal quality.

- Optical power monitoring capability: Helps monitor optical signal transmission status in real time.

- Connector plugging and unplugging life: determines the long-term reliability of the patch panel.

- Compact appearance design: affects the space utilization efficiency of the patch panel.

In short, with its excellent optical transmission performance, sturdy and durable mechanical structure, and compact and highly integrated design features, LC optical fiber distribution frame plays an important role in meeting the needs of high-density optical fiber cabling. It is an important part of the current optical fiber network construction. one of the key equipment.

Main types of LC fiber optic distribution frames

Let me introduce to you the main types of LC fiber optic distribution frames, as well as their differences and values in different application scenarios:

Common subtypes of LC patch panels:

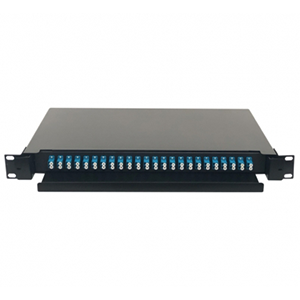

- Cabinet-type LC patch panel: installed in a standard 19-inch communication cabinet, providing high-density port capacity.

- Rack-mounted LC patch panel: Installed in a standard rack system, the appropriate unit height can be selected according to needs.

- Wall-mounted LC patch panel: It adopts an independent wall-mounted design and is suitable for wiring management of small optical fiber networks.

- Modular LC patch panel: adopts a detachable modular design for flexible expansion and maintenance.

Differences between various types of LC patch panels in terms of applicable scenarios, port density, etc.:

- Cabinet type: suitable for large-capacity optical fiber cabling scenarios such as large data centers and telecommunications networks.

- Rack type: Suitable for medium-sized applications such as integrated wiring and fiber optic management in computer rooms.

- Wall-mounted: Suitable for small and medium-sized networks, home/office optical fiber access and other small-scale applications.

- In terms of port density, the cabinet type has the highest port density, up to 288 or more ports; other types follow.

The application value of different LC patch panels in optical fiber network cabling:

- Cabinet type: supports high-density optical fiber cabling, which is conducive to the orderly management of large-scale networks.

- Rack-mounted: Flexible and adaptable, it can meet the optical fiber wiring needs of medium-sized networks.

- Wall-mounted: Easy to install and maintain, suitable for optical fiber access and wiring of small networks.

- Modularization: It can be flexibly expanded according to actual needs and is conducive to the progressive construction of the network.

In short, LC fiber optic patch panel plays an indispensable role in the field of fiber optic network cabling with its compact and high-density design features and diversified products suitable for networks of different sizes. According to the needs of actual application scenarios, rational selection of the type of LC patch panel can help improve the deployment flexibility and management efficiency of optical fiber networks.

Installation and management of LC optical fiber distribution frame

Let me introduce to you the installation and management of LC optical fiber distribution frame:

Correct installation process and precautions for LC patch panel:

- Choose a suitable installation location and ensure there is sufficient maintenance space around the patch panel.

- Follow the instructions and securely install the patch panel on the cabinet or rack.

- Introduce fiber optic cables and route them in an orderly manner according to rules to avoid cable entanglement.

- Make sure that the optical fiber connector and the patch panel port are completely connected without tilt or other problems.

- Finally, check whether the entire wiring system is installed securely and whether the optical fiber interface is normal.

Daily inspection and maintenance management methods of LC patch panel:

- Regularly check the appearance of the patch panel to ensure there is no mechanical damage, contamination or other problems.

- Check whether the optical fiber connection is firm and there is no looseness.

- Check the cleanliness of the fiber end face and clean it if necessary.

- For patch panels equipped with optical power monitoring, check the optical power data regularly.

- Keep the optical fiber wiring inside the patch panel clean and orderly to improve maintenance efficiency.

Common faults of LC distribution frame and their troubleshooting measures:

- The optical signal transmission loss is too high: Check whether the optical fiber connection is firm and whether the end face is clean. Reclean the connector and reconnect it.

- Some ports cannot be connected normally: Check whether the port connection mechanism is damaged. Replace damaged ports or entire patch panel modules.

- Messy fiber optic cable management: Rearrange the wiring to ensure orderly management of fiber optic cables. Adjust the drawer routing of the patch panel if necessary.

In general, correct installation of LC patch panels and regular maintenance and inspection are the keys to ensuring the stable operation of optical fiber networks. Pay attention to the installation process, keep the connections clean, and detect and eliminate faults in time, which is very important to give full play to the performance of the LC patch panel.

Application of LC optical fiber distribution frame in optical fiber network

Let me introduce to you the typical applications of LC fiber optic patch panels in different fiber optic network application scenarios and its important role in achieving high-density cabling:

Application of LC patch panel in data center network:

- Data centers have high requirements for the density and manageability of optical fiber cabling.

- LC patch panel can support high-density optical fiber connections with its small and compact design.

- Through modular management, it helps to optimize the fiber layout inside the data center.

Application of LC distribution frame in operator’s optical fiber network:

- Operator networks require large-scale, long-distance optical fiber transmission capabilities.

- LC patch panel can effectively manage large-capacity optical fiber connections and improve network maintainability.

- In key nodes such as telecommunications equipment rooms and central offices, LC patch panels play a key role.

Application of LC distribution frame in building fiber optic cabling:

- Building fiber optic access networks require flexible and scalable cabling solutions.

- The modular design of LC distribution frame can easily meet the needs of different floors and departments.

- Wall-mounted LC patch panel is particularly suitable for cabling management of optical fiber networks in small buildings.

The important role of LC patch panels in achieving high-density wiring:

- The bandwidth demand of optical fiber networks continues to grow, placing higher requirements on wiring density.

- With its compact size, the LC patch panel can achieve high-density wiring in a limited space.

- High-density optical fiber cabling management helps improve the transmission performance of the entire optical fiber network.

- It is one of the key technologies to meet the construction needs of future high-bandwidth optical fiber networks.

In general, LC fiber optic patch panels are widely used in various fiber optic network scenarios such as data centers, carrier networks, and building fiber optic access due to their excellent high-density wiring characteristics. It plays an important role in meeting the growing bandwidth demands of optical fiber networks and is one of the key supporting technologies for future optical fiber network construction.

Summary

LC fiber optic distribution frame is undoubtedly the best choice in fiber optic network construction. Its excellent optical performance, high integration level and wide range of applicable scenarios all highlight the important status of lc fiber patch panel. Whether in data centers, carrier networks or other fields, LC patch panels can inject powerful power into your optical fiber network and ensure high-density and orderly optical fiber cabling.

We provide professional fiber optic patch panel products and installation management services, and are equipped with an experienced technical team to provide you with considerate guidance at any time. If you have any questions about selecting or using LC patch panels, please feel free to contact us for communication.

LC Fiber Patch Panel FAQ

An LC fiber patch panel is a network equipment component used to organize, manage, and provide connectivity for LC-type fiber optic cables in fiber optic networks and installations.

LC fiber patch panels typically include features such as pre-installed LC adapter ports, cable management guides, labeling spaces, and a modular design to accommodate a variety of fiber counts and configurations.

The primary purpose of an LC fiber patch panel is to provide a centralized and organized point of interconnection for LC-terminated fiber optic cables, enabling easy patching, testing, and maintenance of fiber optic connections.

LC fiber patch panels are extensively used in telecommunications, data centers, enterprise networks, and other fiber optic installations where high-density, organized fiber management is required.

The main difference is the use of the LC (Lucent Connector) fiber optic connector type, which is smaller and more compact compared to other connector types like SC or ST.

Key advantages include high-density fiber management, easy access for patching and troubleshooting, improved cable organization, and compatibility with the widely-used LC connector.

LC fiber patch panels are available in a wide range of fiber counts, typically ranging from 12 to 144 fiber ports, and can be configured for either simplex (single-fiber) or duplex (dual-fiber) connections.

LC fiber patch panels are typically mounted in standard 19-inch equipment racks or cabinets and connected to the fiber optic cabling infrastructure using pre-terminated LC patch cables.

Best practices include proper cable routing, strain relief, labeling, and regular inspection and cleaning to ensure the continued reliability and performance of the fiber optic connections.

Accessories such as cable management accessories, fiber optic test equipment, and specialized cleaning tools can enhance the functionality and maintain the integrity of the LC fiber patch panel installation.