The MPO interface undoubtedly plays a key role in high-density fiber connections. This article will compare the characteristics of MPO male and MPO female connectors. We will first define the physical structure and technical standards of the MPO interface and explain its role in the fiber optic network. Next, we will describe the appearance and connection characteristics of the MPO male connector, as well as the physical structure and connection principle of the MPO female connector, and analyze the advantages and application scenarios of the two in use.

We will compare the MPO male and female connectors in terms of physical structure, connection method, etc., and analyze the key factors affecting the selection. In addition, we will give examples of the combined use of MPO male and female connectors in the network and introduce their advantages in different application scenarios. Finally, we will summarize the main considerations for the selection of MPO male and female connectors and provide specific operational suggestions for installation and debugging.

Basic concepts of MPO interfaces

Let me introduce you to the basic concepts of the MPO (Multi-fiber Push-On) interface, including its physical structure and technical standards, and its role in the fiber optic network.

Physical structure and technical standards of MPO interface:

1. Physical structure:

- MPO interface is a multi-core fiber interface that can connect 8, 12 or 16 optical fibers at one time.

- It consists of a pluggable connector on the front and back, and has a compact structure.

2. Technical standards:

- MPO interface follows international standards such as IEC 61754-7 and has standardized dimensions and performance indicators.

- Common MPO specifications include MPO-8, MPO-12, MPO-16, etc., which indicate the number of optical fibers in a single interface.

The role of MPO interface in optical fiber network:

1. High-density optical fiber wiring:

- MPO interface can realize large-capacity, high-density optical fiber wiring and interconnection.

- It is conducive to improving the wiring efficiency and space utilization of optical network system.

2. Easy to install and deploy:

- MPO interface adopts plug-and-play design, without complicated single-core optical fiber fusion.

- It speeds up the deployment and maintenance of optical fiber network.

3. Support wavelength division multiplexing:

- MPO interface can cooperate with wavelength division multiplexing technology (CWDM/DWDM) to realize the multiplexing of multi-wavelength channels.

- It helps to further improve the transmission capacity of the optical network.

4. Reliable optical transmission:

- The MPO interface adopts a precise optical alignment structure to ensure the reliability of the transmission link.

- It plays an important role in high-speed optical transmission.

In short, as a high-density, easy-to-use, wavelength division multiplexing-supported optical fiber connection solution, the MPO interface has been widely used in modern optical fiber networks and is one of the key technologies for building high-performance optical transmission systems.

Main features of MPO male connectors

Let me introduce you to the main features of the MPO male connector, including its appearance, connection characteristics, and advantages and application scenarios in use.

Appearance and connection characteristics of MPO male connector:

1. Appearance overview:

- The MPO male connector is rectangular in shape and compact in size.

- The surface is provided with raised positioning keys to ensure the correct plugging and unplugging direction.

2. Connection characteristics:

- The MPO male connector can connect 8, 12 or 16 optical fiber cores at the same time.

- The push-pull connection method is adopted, which is simple and quick to operate.

- It can be reliably fixed on the MPO female connector through the positioning key and lock design.

Advantages and application scenarios of MPO male connectors in use:

1. Advantages of high-density wiring:

- A single MPO interface can carry a large number of optical fibers, which is conducive to high-density wiring.

- It is widely used in data centers, computer rooms and other space-constrained scenarios.

2. Convenient installation features:

- MPO male connectors adopt a plug-and-play design, without the need for single fiber splicing.

- The complexity of on-site wiring and maintenance is greatly simplified.

3. Reliable transmission performance:

- MPO connectors have a precise optical path alignment mechanism to ensure reliable transmission of optical signals.

- Applicable to various types of optical fiber communication systems that require high transmission quality.

4. Support wavelength division multiplexing:

- MPO interface is compatible with CWDM/DWDM wavelength division multiplexing technology.

- Can meet the needs of high-speed and large-capacity optical networks.

In summary, MPO male connectors are widely used in various types of optical fiber communication systems due to their advantages such as high density, convenient installation, and reliable transmission, and play an important role in achieving high-performance optical transmission.

Main features of MPO female connectors

Let me introduce you to the main features of MPO female connectors, including its physical structure and connection principle, as well as its differences from MPO male connectors.

Physical structure and connection principle of MPO female head:

1. Physical structure:

- The MPO female head is the fixed end of the MPO interface and is installed on the device or panel.

- It contains multiple precise fiber positioning holes for optical alignment with the MPO male head.

2. Connection principle:

- The fiber core on the MPO male head is correspondingly inserted into the positioning hole of the female head.

- Through the positioning key, lock buckle and other structures, a reliable fiber docking connection is achieved.

- This docking method ensures the accuracy and stability of optical coupling.

The difference between the MPO female and the male:

1. Installation:

- The MPO female is fixedly installed on the device or panel, while the male is pluggable.

- The female requires professional installation and wiring.

2. Fiber positioning:

- The MPO female contains precise fiber positioning holes to ensure accurate alignment with the male.

- The male uses the shell structure to roughly align the fiber.

3. Coupling stability:

- The connection between the MPO female and the male is more stable and reliable, and has excellent anti-vibration performance.

- This makes the female connector more suitable for application scenarios that require long-term stable transmission.

4. Maintenance cost:

- Once the MPO female connector is installed, the maintenance and replacement costs are relatively high.

- The male connector can be flexibly replaced, and the maintenance cost is relatively low.

In short, there are certain differences between the MPO female connector and the male connector in terms of installation form, fiber alignment, coupling stability, etc., and it is necessary to select the appropriate interface type according to the specific application scenario.

Comparison of the difference between MPO male connector and MPO female connector

Let me compare the MPO male connector and the MPO female connector in terms of physical structure, connection method, etc., and analyze the key factors that affect the selection of male or female connectors.

Comparison between MPO male and MPO female:

1. Physical structure:

- MPO male is pluggable and has a compact appearance.

- MPO female is fixedly installed on the device or panel, and the overall structure is more complex.

2. Connection method:

- MPO male adopts push-pull quick connection, which is easy to operate.

- MPO female and male need to be accurately aligned and fixed when connected.

3. Optical alignment:

- MPO male relies on the shell structure for rough fiber alignment.

- MPO female has precise fiber positioning holes inside, which makes alignment more accurate.

4. Installation and maintenance:

- MPO male connectors can be flexibly replaced, and the maintenance cost is low.

- Once the MPO female connector is installed, the maintenance and replacement costs are relatively high.

Key factors affecting the selection of male or female connectors:

1. Application environment:

- For data centers and computer rooms, where high-density wiring is required, it is more suitable to use MPO female connectors.

- For occasions that require frequent connection/disconnection, MPO male connectors are more suitable.

2. Transmission performance requirements:

- For systems that have higher requirements for transmission reliability and stability, MPO female connectors have more advantages.

- For situations where the coupling accuracy requirements are relatively low, you can choose the MPO male connector.

3. Maintenance cost considerations:

- If the system needs frequent maintenance and upgrades, the flexibility of the MPO male connector is more advantageous.

- For scenarios with long-term stable operation, the overall maintenance cost of the MPO female connector may be lower.

In summary, the MPO male connector and female connector have their own characteristics. It is necessary to weigh the physical structure, connection method, transmission performance, maintenance cost and other factors according to the needs of the actual application scenario to select the appropriate interface type.

Application practice of MPO connection solution

Let me introduce you to the combined use of MPO male connector and female connector in the optical fiber network, as well as the advantages of the MPO connection solution in different application scenarios.

Combined use of MPO male and female connectors in the network:

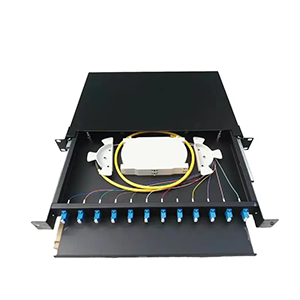

1. Data center/computer room wiring:

- In large-capacity fiber wiring, MPO female connectors are often used in rack panels or equipment ports.

- MPO male connectors are used to connect to fiber jumpers or distribution boxes to achieve flexible wiring.

2.FTTH/PON access network:

- In fiber-to-the-home (FTTH) or passive optical network (PON), MPO female connectors can be used for optical splitters or OLT devices.

- MPO male connectors are suitable for fiber distribution frames or ONT devices, which are convenient for quick on-site connection.

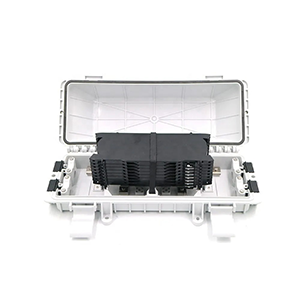

3. Passive optical network handover:

- At the junction between the user side and the operator side of the PON network, the MPO interface can easily realize optical fiber interconnection.

- The MPO female head is installed in the handover box, and the MPO male head is used for optical fiber wiring on the user side.

Advantages of MPO connection solutions in different application scenarios:

1. High-density wiring advantages:

- The MPO interface can carry a large number of optical fibers in a limited space, improving wiring efficiency.

- It is very suitable for scenarios with high space utilization requirements such as data centers and computer rooms.

2. Convenience of deployment and installation:

- The plug-and-play design of the MPO male head greatly simplifies on-site wiring and maintenance.

- Especially suitable for access networks and handover scenarios that require rapid deployment.

3. Transmission performance advantages:

- The reliable optical alignment mechanism of the MPO interface ensures long-term stable optical transmission quality.

- More suitable for trunk backbone network applications that require high transmission reliability.

4. Support wavelength division multiplexing:

- The MPO interface can be combined with CWDM/DWDM technology to meet large-capacity transmission needs.

- It is conducive to further improving the transmission capacity and efficiency of optical networks.

In short, the flexible combination of MPO male and female connectors in network applications has played many advantages such as high-density wiring, convenient deployment, and reliable transmission. It is one of the key technologies for building high-performance optical fiber networks.

Notes on MPO interface selection, installation and debugging

Okay, let me summarize the main factors to consider when choosing MPO male and female connectors, and provide specific operational suggestions for MPO interface installation and debugging.

Main considerations for selecting MPO male and female connectors:

1. Application scenario requirements:

- Determine the required number of fiber channels (8, 12 or 16 cores)

- Choose the appropriate interface type based on the space, wiring and other characteristics of the application environment

2. Transmission performance requirements:

- Evaluate the degree of demand for indicators such as optical alignment accuracy and coupling stability

- Choose MPO female or male connector based on performance requirements

3. Maintenance cost considerations:

- Estimate the complexity and frequency of interface installation and maintenance

- Choose a lower-cost interface type when performance is met

4. Compatibility requirements:

- Ensure that the selected MPO interface is fully compatible with existing equipment, optical fibers, etc.

- Avoid problems such as optical performance or physical matching

Specific operational suggestions for MPO interface installation and debugging:

1. Installation preparation:

- Choose a clean and dry working environment to reduce the impact of dust on optical fiber

- Prepare the necessary tools, such as optical fiber stripping tools, optical fiber cleavers, etc.

2. Interface installation:

- Carefully peel off the optical fiber protective layer according to the manufacturer’s instructions to ensure the end face is clean

- Use the optical fiber cleaver to accurately cut the optical fiber to ensure that the end face is flat and free of burrs

- Correctly insert the optical fiber end into the MPO interface to ensure a reliable connection

3. Performance test:

- Measure the optical power at each output end to verify whether the expected transmission performance is achieved

- If necessary, adjust the fiber length and angle to optimize the coupling effect of the MPO interface

4. Labeling and fixing:

- Clearly label the installed MPO interface for subsequent maintenance

- Fix the fiber interface with heat shrink tubing to prevent accidental detachment

In short, reasonably selecting the type of MPO interface and following the correct installation and commissioning steps will help ensure the reliability and service life of the MPO connection solution in actual applications.

Summary

Rational selection and correct deployment of MPO interfaces are crucial to building high-density fiber networks. Our company has long focused on the research and development and application of optical communication technology and has rich industry experience. Our MPO series products have reached the industry-leading level in terms of optical performance and reliability, and can meet your demanding network needs.

Whether you need to deploy in a data center or a wide area network environment, we can provide you with customized MPO connection solutions. At the same time, our professional team will provide you with comprehensive technical support, including on-site surveys, solution design, and installation and debugging guidance. Contact us now to learn more about the MPO interface.

MPO Male And MPO Female FAQ

MPO (Multi-fiber Push-On/Pull-Off) is a fiber optic connector type designed to provide high-density connectivity for multiple optical fibers in a single connector.

The main difference is the arrangement of the optical fiber terminations:MPO male has the optical fiber tips protruding outwards.MPO female has the optical fiber tips recessed inwards.

You can visually inspect the connector face to see if the fiber tips are protruding (male) or recessed (female).

MPO male and female connectors are designed to mate with each other, allowing the optical fibers to align and connect properly.

They are widely used in high-density fiber optic patch panels, switch/router interfaces, and fiber optic cabling systems.

No, MPO male connectors cannot be directly mated together. They require an MPO female connector in between to act as an adapter.

Proper alignment and keying features on the connectors help ensure the optical fibers mate correctly during the connection process.

Key advantages include increased fiber density, faster installation, and more efficient fiber management in fiber optic networks.

When properly mated, there should be no significant performance differences, as the optical interface is the same.

Advancements include higher fiber count versions (e.g., MPO-12, MPO-24), improved ferrule materials, and the integration of MPO connectors with other fiber optic components.